Home > Super Duplex Steel > Super Duplex Steel Boiler Tubing

Aman Pipes and Tubes, headquartered in Hyderabad, India, is a recognized manufacturer and supplier of Stainless Steel Boiler Tubing engineered for high performance in elevated temperature and pressure environments. Our boiler tubes are crafted with precision using premium stainless steel grades and advanced manufacturing processes to ensure superior corrosion resistance, thermal strength, and long-term reliability. Designed to meet international standards such as ASTM A213, A249, and A269, our SS boiler tubing serves critical applications across power plants, refineries, and chemical industries. With a commitment to quality, timely delivery, and customer satisfaction, we serve clients across India and global markets.

Stainless Steel Boiler Tubing is typically available in grades such as 304, 304H, 316, 316H, and 321. The composition includes 18–20% chromium, 8–14% nickel, and for certain grades, 2–3% molybdenum or titanium for enhanced high-temperature stability and corrosion resistance. These tubes offer tensile strength from 500 to 750 MPa and yield strength from 200 to 400 MPa. With excellent elongation, creep resistance, and oxidation resistance, SS boiler tubes maintain structural integrity under fluctuating temperatures and pressure conditions, making them ideal for long-term use in critical boiler and heat exchanger systems.

| Specifications | ASTM A789 ASME SA789 |

| Dimensions | ASTM, ASME and API |

| Tube Size | 1/2″NB TO 12 “NB IN |

| Specialized in | Large Diameter Size |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80 |

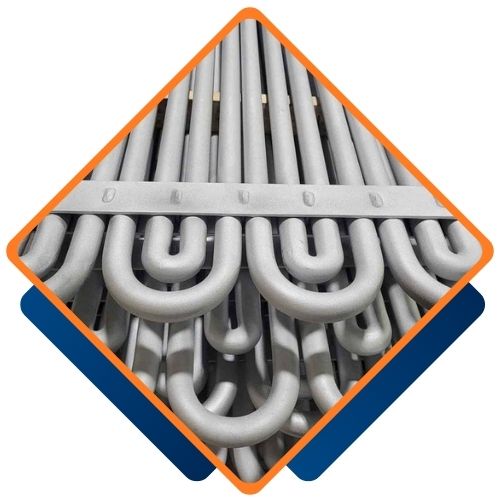

| Type | Fire Boiler Tubing/ Hot Rolled Boiler Tube/ Heat Expansion Boiler Tube/ IBR Seamless Boiler Tubes |

| Material | Super Duplex Steel |

|---|---|

| Carbon (C) Max. | 0.030 |

| Manganese (Mn) Max. | 1.20 |

| Phosphorous (P) Max. | 0.035 |

| Sulphur (S) Max. | 0.020 |

| Silicon (Si) Max. | 0.80 |

| Chromium (Cr) | 24.0–26.0 |

| Nickel (Ni) | 6.0–8.0 |

| Molybdenum (Mo) | 3.0–5.0 |

| Nitrogen (N) | 0.24–0.32 |

| Iron (Fe) | Bal. |

| Copper (Cu) | 0.50 |

| Other Elements | — |

| Tensile Strength | Yield Strength | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Alloy | UNS Designation | Spec. | psi | MPa | ksi | psi | MPa | ksi | Elongation in 2 in. (min.) % | Grain Size Req. | Max. Hardness | Modulus of Elasticity (x106psi) | Mean Coefficient of Thermal Expansion (IN./IN./°F x 10-6) | Thermal Conductivity (BTU-in/ ft2-h-°F) |

| Super Duplex | – | A789, A790 | 100,000 | 690 | 100 | 70,000 | 485 | 70 | 20 | — | 30.5 Rc | — | — | — |

| Super Duplex | – | A789, A790 | 116,000 | 800 | 116 | 80,000 | 550 | 80 | 15 | — | 32 Rc | 27.5 | 7.2 | |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Super Duplex Steel Boiler Tubing from Aman Pipes and Tubes ensures superior quality and durability, offering outstanding corrosion resistance and high strength. Our dedication to delivering exceptional service and reliable products guarantees customer satisfaction across a wide range of industrial applications. With our expertise in Duplex steel solutions, you can trust us to provide a top-tier, customized piping solution that meets your specific requirements.

Aman Pipes and Tubes, one of the largest suppliers of Super Duplex Steel Boiler Tubing in the Hyderabads, India. Offers a wide range of high-quality pipes and tubes designed for various industrial applications. Their extensive inventory and dedication to exceptional service make them a trusted choice for Super Duplex steel products in the region, delivering reliable solutions to meet diverse project requirements.

Yes, we provide custom sizes for Super Duplex Steel Boiler Tubing to meet your specific requirements. At Aman Pipes and Tubes, our team is dedicated to delivering tailored solutions for all your piping and tubing needs. For more information, please contact us at sales@amanpipesandtubes.co.in.

Stainless Steel Boiler Tubing from Aman Pipes and Tubes is widely used in industries where exposure to high temperatures and corrosive gases or fluids is constant. These tubes are ideal for power generation boilers, superheaters, economizers, and heat exchangers in thermal and nuclear power plants. In petrochemical and refinery operations, they’re used for high-pressure steam and process lines. Their resistance to thermal fatigue and oxidation also makes them suitable for marine boilers, waste heat recovery units, and chemical processing equipment. With high performance and low maintenance, SS boiler tubing is a preferred choice for safe and efficient thermal systems.

©2024 Aman Pipes and Tubes . All Rights Reserved.