Home > Stainless Steel > Stainless steel 904L Welded Tubing

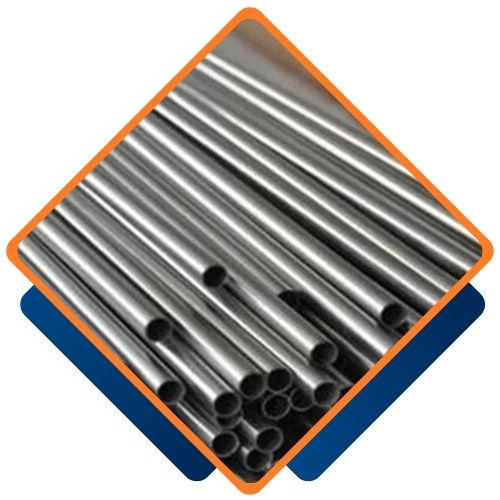

Aman Pipes and Tubes is a leading producer and exporter of Stainless Steel 904L Welded Tubing in Hyderabad, India. Established as a credible partner for quality and accuracy, the company provides tubing solutions that satisfy various industrial requirements and uses. Its 904L welded tubing is designed on the basis of latest technology and strict quality check to provide maximum durability, corrosion resistance, and strength. With client satisfaction and timely delivery guaranteed, Aman Pipes and Tubes caters to industries like chemical processing, marine, pharmaceuticals, and power generation, offering custom size and dependable service for domestic and overseas markets.

904L Welded Tubing Stainless Steel consists of iron with high chromium (19–23%), nickel (23–28%), molybdenum (4–5%), and copper (1–2%) small additions for enhanced corrosion resistance. The density is 8.0 g/cm³, tensile strength is approximately 490 MPa, and yield strength of 220 MPa, with good elongation of 35% minimum. It shows enhanced resistance to acidic environments as well as stress corrosion cracking and is suitable for harsh service conditions.

| Specifications | ASTM B673, B677 / ASME SB673, SB 677 |

|---|---|

| Dimensions | ASTM, ASME and API |

| SS 904L Pipes | 1/2″ NB – 16″ NB |

| ERW 904L Pipes | 1/2″ NB – 24″ NB |

| EFW 904L Pipes | 6″ NB – 100″ NB |

| Size | 1/8″NB TO 30″NB IN |

| Specialized in | Large Diameter Size |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

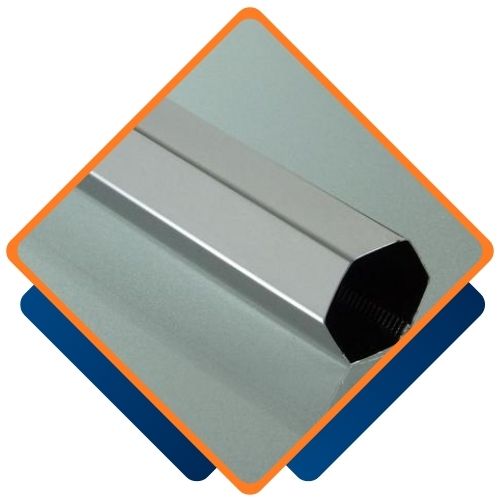

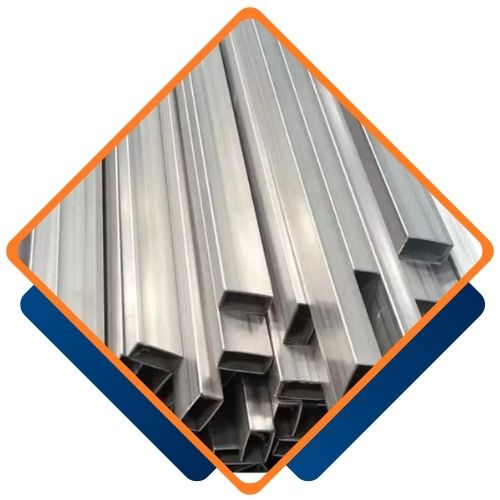

| Form | Round, Square, Rectangular, Hydraulic Etc |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |

| Grade | C | Mn | Si | P | S | Cr | MO | Ni | CU | |

|---|---|---|---|---|---|---|---|---|---|---|

| 904L | Min | – | – | – | – | – | 19.0 | 4.00 | 23.00 | 1.00 |

| max | 0.20 | 2.00 | 1.00 | 0.045 | 0.035 | 23.0 | 5.00 | 28.00 | 2.00 |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) | Brinell (HB) | ||||

|---|---|---|---|---|---|

| 904L | 490 | 220 | 35 | 70-90 typical | – |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choose Stainless Steel 904L Welded Tubing from Aman Pipes and Tubes for exceptional corrosion resistance, superior strength and excellent durability. Ideal for a variety of industrial applications it provides outstanding performance in harsh environments. With precision manufacturing and quality assurance, we ensure reliable and durable tubing solutions.

Aman Pipes and Tubes is the largest supplier of Stainless Steel 904L Welded Tubing in Hyderabad, India. Known for its high-quality products. We offer superior corrosion resistance, strength, and durability. Trusted by industries worldwide they provide reliable precision-engineered tubing for various applications and project needs.

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | KS | EN |

|---|---|---|---|---|---|---|---|

| SS 904L | 1.4539 | N08904 | SUS 890L | Z2 NCDU 25-20 | 904S13 | STS 317J5L | X1NiCrMoCu25-20-5 |

Yes, Aman Pipes and Tubes offer large custom designs for Stainless Steel 904L Welded Tubing. With design, wall thickness and length. Their adjustable options ensure the tubing meets specific application requirements. This flexibility makes it more efficient and reliable for different industries and environments. For more details, contact us at sales@amanpipesandtubes.co.in.

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Co-eff of Thermal Expansion (µm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100°C (J/kg.K) | Elec Resistivity (nΩ.m) | |||

| 0-100°C | 0-315°C | 0-538°C | At 20°C | At 500°C | |||||

|---|---|---|---|---|---|---|---|---|---|

| 904L | 8000 | 200 | 15 | – | – | 13 | – | 500 | |

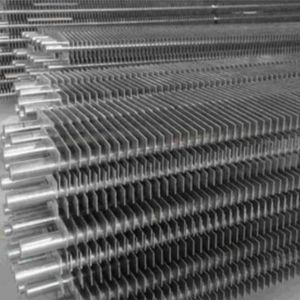

Stainless Steel 904L Welded Tubing is found in general use across industries that necessitate high corrosion resistance and material stability. Typical end-use applications are chemical process equipment, heat exchangers, oil and gas refineries, marine components, paper and pulp mills, and chemical handling equipment. Its high corrosion resistance against sulfuric, phosphoric, and acetic acids renders it fit for use in hostile chemical environments. It is also applied in pollution control systems, power plant condensers, and in drug manufacture because it is non-reactive and has long-term strength in severe working conditions.

©2024 Aman Pipes and Tubes . All Rights Reserved.