Home > Stainless Steel > Stainless Steel 347 and 347H Welded Pipes

Aman Pipes and Tubes, based in Hyderabad, India, has built a solid reputation as a reliable manufacturer and supplier of Stainless Steel 347 and 347H Welded Pipes. They provide strong and corrosion-resistant piping solutions that cater to critical industries. These stabilized austenitic stainless steels are enhanced with niobium (columbium) to improve their resistance to intergranular corrosion, even after welding or exposure to high temperatures. SS 347 is perfect for general high-temperature applications, while SS 347H, with its higher carbon content, offers better creep strength. Aman Pipes and Tubes guarantees that each product meets global quality standards, making them a trusted choice for petrochemical, refinery, aerospace, and heat processing sectors.

Stainless Steel 347/347H Welded Pipes are primarily made up of Chromium (17–20%), Nickel (9–13%), and Niobium (Nb + Ta: 10xC–1.0% max), which ensure excellent stability against sensitization. SS 347 has a carbon content of ≤0.08%, while SS 347H contains 0.04–0.10% carbon, enhancing its high-temperature strength. These pipes typically boast a tensile strength of 515 MPa, yield strength of 205 MPa, and an elongation of 35%. They are non-magnetic, offer great weldability, and maintain their mechanical integrity even under prolonged exposure to high temperatures and stress, making them ideal for elevated temperature applications.

Specifications : ASTM A312 / ASME SA312

Outside Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24″ NB available Ex-stock, OD Size available Ex-stock

Thickness : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Size : 1/2″ NB – 24″ NB

Type : Welded

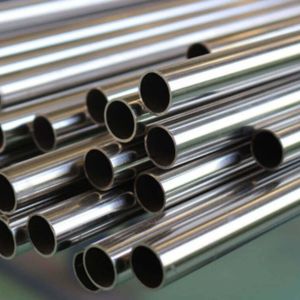

Form: Round Pipes, Square Pipes, Rectangular Pipes.

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN |

| SS 347 | 1.4550 | S34700 | SUS 347 | 08Ch18N12B | X6CrNiNb18-10 |

| SS 347H | 1.4961 | S34709 | SUS 347H | – | X6CrNiNb18-12 |

| Grade | C | Mn | Si | P | S | Cr | Cb | Ni | Fe |

| SS 347 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 20.00 | 10xC – 1.10 | 9.00 – 13.00 | 62.74 min |

| SS 347H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 8xC – 1.10 | 9.0 -13.0 | 63.72 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 347 and 347H Welded Pipes guarantees excellent corrosion resistance, high strength, and durability. Designed for diverse industrial applications, it delivers reliable performance in tough environments while maintaining competitive pricing for cost-effective solutions.

Aman Pipes and Tubes, a leading manufacturer and supplier of Stainless Steel 347 and 347H Welded Pipes in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubing suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us a trusted choice for regional products.

| NB Sizes | Sch 5 | Sch 10 | Sch 40 | Sch 80 | Sch 160 |

| 1/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/4″ | ✓ | ✓ | ✓ | ✓ | |

| 3/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 5″ | ✓ | ✓ | ✓ | ✓ | |

| 6″ | ✓ | ✓ | ✓ | ✓ |

We offer custom sizes for Stainless Steel 347 and 347H Welded Pipes to meet your specific needs. Our dedicated team at Aman Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@amanpipesandtubes.co.in.

Stainless Steel 347 and 347H Welded Pipes are widely utilized in industries that require high-temperature strength, corrosion resistance, and stability after welding. You’ll find them in heat exchangers, furnace components, boiler tubes, and superheater tubes in power plants. These pipes are also commonly used in chemical processing, petroleum refining, aerospace, and marine environments where thermal cycling and corrosion are significant concerns. SS 347 is often chosen for general thermal service, while SS 347H is preferred when higher creep resistance is needed. Their ability to endure pressure and oxidation at elevated temperatures makes them a go-to choice for many applications.

©2024 Aman Pipes and Tubes . All Rights Reserved.