Home > Stainless Steel > Stainless Steel 321/321H Heat Exchanger Tubing

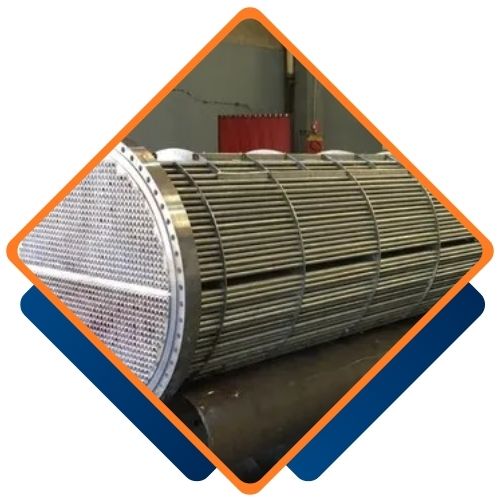

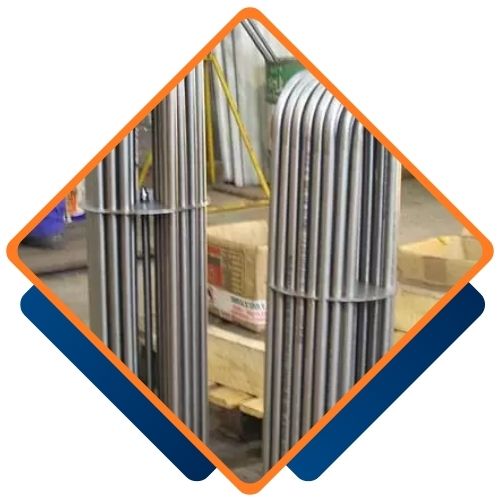

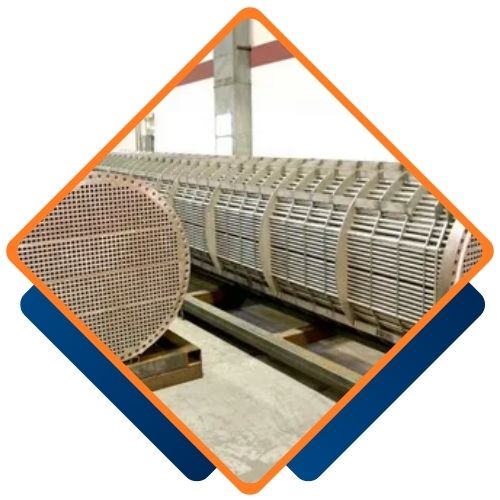

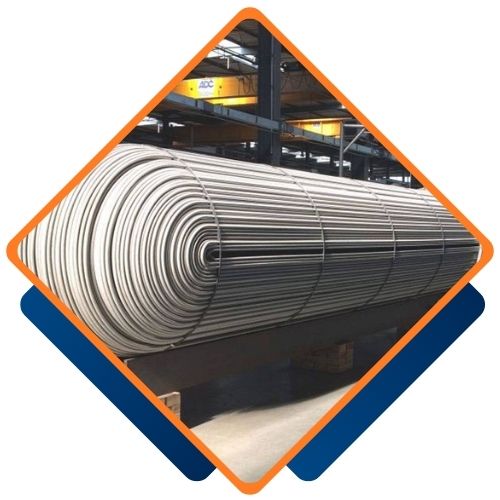

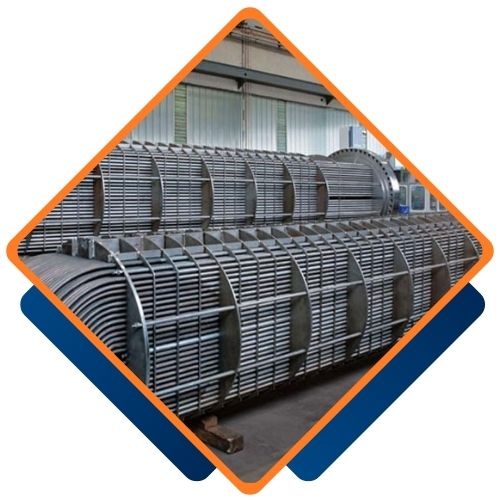

Aman Pipes and Tubes, a prominent manufacturer and supplier based in Hyderabad, India, is dedicated to providing top-notch Stainless Steel 321/321H Heat Exchanger Tubing. This tubing is specifically designed for applications that require exceptional heat and corrosion resistance. SS 321 is a titanium-stabilized austenitic stainless steel that effectively prevents intergranular corrosion after welding, while SS 321H, its high-carbon counterpart, is perfect for high-temperature environments due to its enhanced creep strength. These heat exchanger tubes are meticulously engineered to ensure high thermal efficiency, structural integrity, and oxidation resistance. They find extensive use in chemical processing, oil and gas, refineries, and power generation, with Aman guaranteeing consistent product quality that meets global performance and safety standards.

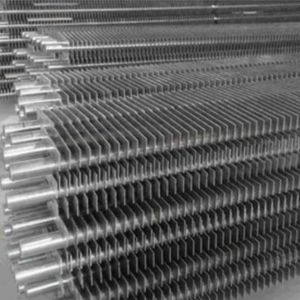

Stainless Steel 321/321H Heat Exchanger Tubing is made up of Chromium (17–19%), Nickel (9–13%), and Titanium (≥5xC%) to prevent carbide precipitation. SS 321H has a higher carbon content (0.04–0.10%) compared to SS 321 (≤0.08%), which enhances its performance under high-temperature stress. These tubes boast a tensile strength of around 515 MPa, yield strength of about 205 MPa, and an elongation of roughly 35%. They are designed to endure oxidation and scaling up to 870°C, offering excellent weldability, mechanical strength, and thermal conductivity. The tubing comes in both seamless and welded forms, making it suitable for critical heat exchange operations in thermal cycling and corrosive environments.

Range : 10 mm OD to 50.8 mm OD

Outer Diameter : 6.00 mm to 101.60 mm

Wall Thickness : 0.70 mm to 8.00 mm

Length : up to 20 m (65.62 ft) Length & Customed Required Length

Specifications : ASTM A 213, A 268, A 269, A 789, Equivalent to ASME, EN, JIS Etc.

| Element | SS 321 | SS 321H |

| C | 0.08 max | 0.04 – 0.10 |

| Mn | 2.0 max | 2.0 max |

| Si | 1.0 max | 1.0 max |

| P | 0.045 max | 0.045 max |

| S | 0.030 max | 0.030 max |

| Cr | 17.00 – 19.00 | 17.00 – 19.00 |

| N | 0.10 max | 0.10 max |

| Ni | 9.00 – 12.00 | 9.00 – 12.00 |

| Ti | 5(C+N) – 0.70 max | 4(C+N) – 0.70 max |

| Element | SS 321/321H |

| Density | 8.0 g/cm3 |

| Melting Point | 1457 °C (2650 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 321/321H Heat Exchanger Tubing from Aman Pipes and Tubes ensures high quality and reliability for your industrial applications. Our tubing is manufactured using premium-grade materials, adhering to strict industry standards, which guarantees durability and performance. We offer customized solutions to meet specific requirements, backed by exceptional customer service and technical support. With our extensive inventory and prompt delivery, you can count on us for timely project execution. Trust Aman Pipes and Tubes for superior stainless steel products that enhance efficiency and longevity in heat exchange systems.

Aman Pipes and Tubes, one of the largest suppliers of Stainless Steel 321/321H Heat Exchanger Tubing in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 321/321H Heat Exchanger Tubing to meet your specific requirements. Our team at Aman Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@amanpipesandtubes.co.in.

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 321 | 1.4541 | S32100 | SUS 321 | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | X12CrNiTi18-9 |

Stainless Steel 321/321H Heat Exchanger Tubing is extensively utilized in industries where high-temperature and corrosion-resistant performance is crucial. Common applications include boilers, condensers, heaters, and air preheaters in power plants, refineries, chemical industries, and marine systems. SS 321 is particularly well-suited for welded components that are exposed to temperatures exceeding 427°C, while SS 321H is preferred for extended service at temperatures above 538°C due to its superior creep strength. These tubes offer remarkable resistance to thermal fatigue and scaling, making them an ideal choice for demanding industrial applications.

©2024 Aman Pipes and Tubes . All Rights Reserved.