Home > Stainless Steel > Stainless Steel 317 and 317L Welded Tubing

Aman Pipes and Tubes is a renowned producer and provider of high-grade Stainless Steel 317 and 317L Welded Tubing in Hyderabad, India. With a reputation for precision engineering and rigorous focus on quality, the company supplies strong, corrosion-resistant tubing solutions for demanding industrial applications. With its advanced manufacturing plant and professional team, Aman Pipes and Tubes follows global standards, gaining confidence among industries like chemical processing, petrochemicals, and pharma. Aman Pipes and Tubes deals in customized tubing in multiple sizes and finishes to guarantee sure performance and on-time delivery according to the specific requirements of its diversified customer base.

Stainless Steel 317 has about 18–20% chromium, 11–15% nickel, 3–4% molybdenum, and low carbon, whereas 317L has a still lower carbon percentage for better corrosion resistance. Both alloys demonstrate outstanding resistance to chemical conditions and heat. Mechanical properties are tensile strength of about 515 MPa, yield strength of 205 MPa, and elongation of at least 35%. These steels have high creep resistance and rupture strength at high stress, with 317L giving enhanced weldability and reduced risk of intergranular attack after welding by virtue of its lower carbon content.

Welded Pipes & Tubes Size : 1 / 8″ NB – 24″ NB

Specifications : ASTM A/ASME SA213, A249, A269, A312, A358

Standard : ASTM, ASME and API

Length : Single Random, Double Random & Required Length

Outer Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB

Thickness : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Types : Welded

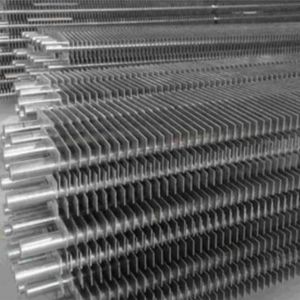

Form : Round Tubes, Square Tubes, Rectangular Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

End : Plain End, Beveled End, Treaded

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choose Stainless Steel 317 and 317L Welded Tubing from Aman Pipes and Tubes for exceptional corrosion resistance, superior strength and excellent durability. Ideal for a variety of industrial applications it provides outstanding performance in harsh environments. With precision manufacturing and quality assurance, we ensure reliable and durable tubing solutions.

Aman Pipes and Tubes is the largest supplier of Stainless Steel 317 and 317L Welded Tubing in Hyderabad, India. Known for its high-quality products. We offer superior corrosion resistance, strength, and durability. Trusted by industries worldwide they provide reliable precision-engineered tubing for various applications and project needs.

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | – |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

Yes, Aman Pipes and Tubes offer large custom designs for Stainless Steel 317 and 317L Welded Tubing. With design, wall thickness and length. Their adjustable options ensure the tubing meets specific application requirements. This flexibility makes it more efficient and reliable for different industries and environments. For more details, contact us at sales@amanpipesandtubes.co.in.

Stainless Steel 317 and 317L Welded Tubing finds applications in a large variety of industry segments that demand superior corrosion resistance and mechanical properties. They are used in chemical and petrochemical plants, flue gas scrubbing systems, power plants, and food processing units. The tubes are also suited for application in marine environments, pulp and paper manufacturing, textile dyeing machinery, and drug manufacturing. They are resistant to corrosive acids and chlorinated chemicals and can hence be used under aggressive conditions. The tubes are also widely applied in heat exchangers, condensers, and process piping networks where high reliability and long service life are required.

©2024 Aman Pipes and Tubes . All Rights Reserved.