Home > Stainless Steel > Stainless Steel 317/317L Seamless Tubing

Aman Pipes and Tubes, a reputable manufacturer and supplier based in Hyderabad, India, specializes in high-performance Stainless Steel 317/317L Seamless Tubing. This tubing is designed to offer outstanding corrosion resistance and durability, especially in harsh chemical environments. SS 317 boasts a higher molybdenum content compared to standard austenitic grades, which gives it remarkable resistance to pitting and crevice corrosion. The low-carbon variant, SS 317L, not only improves weldability but also reduces the risk of intergranular corrosion. These seamless tubes are perfect for high-purity and high-pressure applications. Aman is committed to rigorous quality control, ensuring precise dimensions and adherence to international standards, so you can count on their tubing solutions to perform reliably even in the toughest industrial settings.

Stainless Steel 317/317L Seamless Tubing is made with a blend of Chromium (18–20%), Nickel (11–15%), and Molybdenum (3–4%), which gives it superior corrosion resistance compared to SS 316. The carbon content is kept to ≤0.08% in SS 317 and ≤0.03% in SS 317L, enhancing weldability and minimizing sensitization. Its mechanical properties include a tensile strength of about 515 MPa, yield strength of around 205 MPa, and an elongation of approximately 35–40%. The seamless design guarantees consistent strength and leak-proof performance, making it ideal for high-pressure applications in aggressive environments like acids, salts, and chloride-bearing solutions.

Tube Range : 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A213 / ASTM SA213

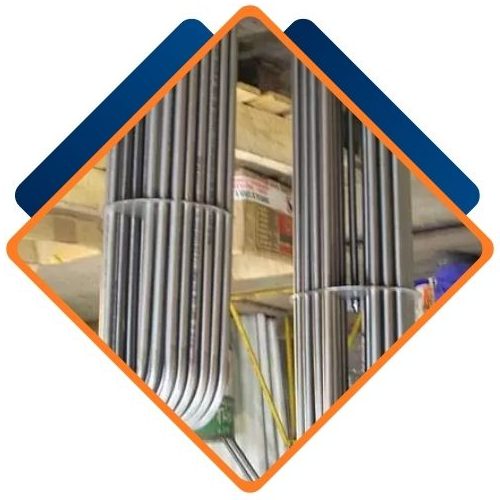

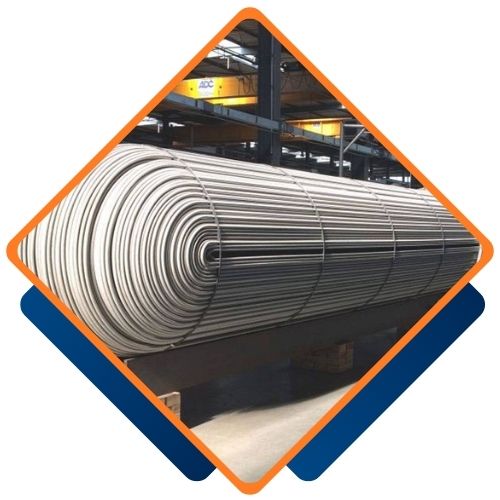

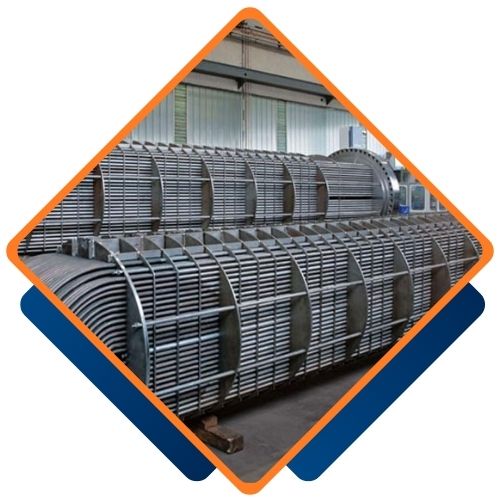

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes

| SS | 317 | 317L |

| Ni | 11 – 14 | 11 – 15 |

| N | – | – |

| Cr | 18 – 20 | 18 – 20 |

| C | 0.08 max | 0.035 max |

| Si | 1 max | 1 max |

| Mn | 2 max | 2 max |

| P | 0.040 max | 0.040 max |

| S | 0.030 max | 0.03 max |

| Mo | 3.00 – 4.00 | 3 – 4 |

| Density | 8.0 g/cm3 |

| Melting Point | 1454 °C (2650 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 317/317L Seamless Tubing from Aman Pipes and Tubes ensures you receive a premium product designed for exceptional performance in corrosive environments. Our tubing features superior corrosion resistance and high strength, making it ideal for applications in chemical processing, pharmaceuticals, and marine industries. With a strong commitment to quality, we employ rigorous testing and quality control measures to guarantee reliability. Additionally, our tailored solutions and expert support ensure that we meet your specific requirements. Trust Brydon for durable, high-quality seamless tubing that enhances the efficiency and safety of your operations.

Aman Pipes and Tubes, one of the largest suppliers of Stainless Steel 317/317L Seamless Tubing in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 317/317L Seamless Tubing to meet your specific requirements. Our team at Aman Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@amanpipesandtubes.co.in.

| Specific Heat (0-100°C) | Thermal Conductivity | Thermal Expansion | Modulus Elasticity | Electrical Resistivity | Density |

| 500 | 14.6 | 16.5 | 193 | 7.4 | 7.99 |

| J.kg-1.°K-1 | W.m -1.°K-1 | mm/m/°C | GPa | μohm/cm | g/cm3 |

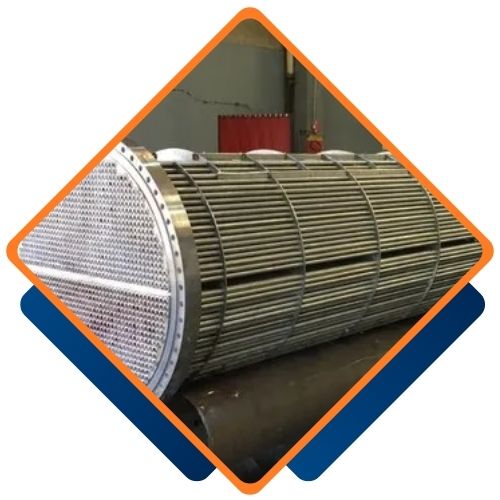

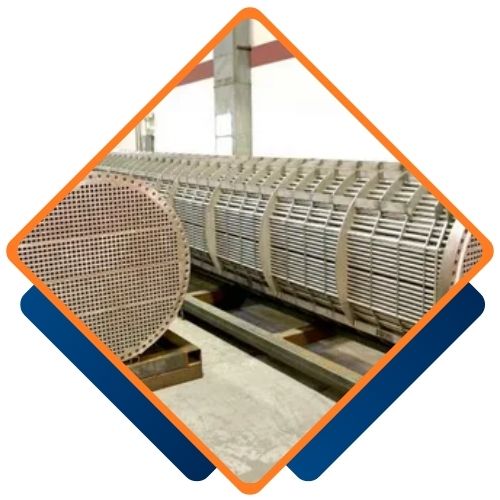

Stainless Steel 317/317L Seamless Tubing finds extensive use across various industries, including chemical processing, pulp and paper, marine, power generation, and pharmaceuticals. These tubes are particularly suited for transporting highly corrosive fluids, such as sulfur compounds, chlorides, and acidic solutions. Common applications include process piping, heat exchangers, condensers, instrumentation lines, and systems for transporting high-purity fluids. SS 317 excels in environments with strong chemical exposure, while SS 317L is the go-to choice for welded systems that require resistance to intergranular corrosion.

©2024 Aman Pipes and Tubes . All Rights Reserved.