Home > Stainless Steel > Stainless Steel 317 and 317L Electropolished Pipes

Aman Pipes and Tubes, established in Hyderabad, India, is a well-known exporter and producer of Stainless Steel 317 and 317L Electropolished Pipes, offering high-end solutions for sectors seeking exceptional corrosion resistance and hygienic processing. Focused on quality, accuracy, and dependability, the organization offers electropolished pipes in diverse specifications to satisfy stringent requirements in industries. Economical, corrosion resistant, and low maintenance, these pipes are particularly ideal for high-purity services. Aman Pipes and Tubes incorporates cutting-edge technology with industry expertise to provide solutions that provide reliable performance and long life in mission-critical operations.

Stainless Steel 317 and 317L Electropolished Pipes consist of around 18–20% chromium, 11–15% nickel, and 3–4% molybdenum, which offer considerable resistance to chemical attack and pitting. The 317L grade, being low in carbon, provides better weldability and less risk of sensitization. These tubes have a tensile strength of about 515 MPa, yield strength of about 205 MPa, and elongation of about 35%. The process of electropolishing improves surface smoothness, corrosion resistance, and cleanliness and is best suited for applications in conditions where purity and sanitation are of utmost importance.

| Specifications | : | ASTM A/ASME SA249/A269/A270 |

| Dimensions | : | ASTM, ASME, and API |

| SS 317 and 317L Pipes Size | : | 1/8″NB TO 30″NB IN |

| Thickness | : | 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10 |

| Finish | : | BA Finish inside and outside, Electropolished finish inside and outside |

| Type | : | Electropolished Pipes & Tubes |

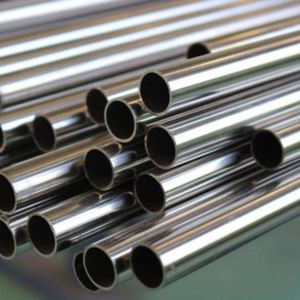

| Form | : | Round, Square, Rectangular, Hydraulic Etc |

| Length | : | Up to 6 meters, custom cut lengths |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 317 and 317L Electropolished Pipes from Aman Pipes and Tubes guarantees excellent corrosion resistance, high strength, and durability. Designed for diverse industrial applications, it delivers reliable performance in tough environments while maintaining competitive pricing for cost-effective solutions.

Aman Pipes and Tubes, a leading manufacturer and supplier of Stainless Steel 317 and 317L Electropolished Pipes in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubing suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us a trusted choice for regional products.

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | – |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

We offer custom sizes for Stainless Steel 317 and 317L Electropolished Pipes to meet your specific needs. Our dedicated team at Aman Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@amanpipesandtubes.co.in.

These pipes are used widely in high corrosion resistance and contamination control industries. In the pharmaceutical and food processing industry, the electropolished surface facilitates minimum bacterial growth and sterilization with ease. In chemical and petrochemical industries, they resist aggressive chemicals and temperatures. Stainless Steel 317 and 317L Electropolished Pipes are also found to be favorable in marine applications because of their superior resistance against chloride-induced corrosion. Other uses involve water treatment plants, pulp and paper mills, and nuclear energy systems, where long-term stability and clean burning are critical.

©2024 Aman Pipes and Tubes . All Rights Reserved.