Home > Stainless Steel > Stainless Steel 316Ti Welded Tubing

Aman Pipes and Tubes, a prominent manufacturer and supplier based in Hyderabad, India, specializes in Stainless Steel 316Ti Welded Tubing, designed for superior performance in high-temperature and corrosive settings. The 316Ti variant is titanium-stabilized, which enhances its resistance to intergranular corrosion and provides remarkable strength even at elevated temperatures. This tubing is perfect for applications that frequently encounter heat or chemical exposure. Aman is committed to precise fabrication and upholding international quality standards, making their 316Ti welded tubing a dependable choice for sectors like petrochemical, pharmaceutical, power generation, and marine processing.

Stainless Steel 316Ti Welded Tubing is crafted with Chromium (16–18%), Nickel (10–14%), Molybdenum (2–3%), and is stabilized with Titanium (at least five times the carbon content) to prevent carbide precipitation. This alloy boasts excellent corrosion resistance along with high creep and stress-rupture strength. Typical mechanical properties include a tensile strength of around 550 MPa, yield strength of about 240 MPa, and an elongation of roughly 35%. The welded design ensures dimensional accuracy and cost-effectiveness, while the titanium addition guarantees long-term stability when exposed to high temperatures and thermal cycling.

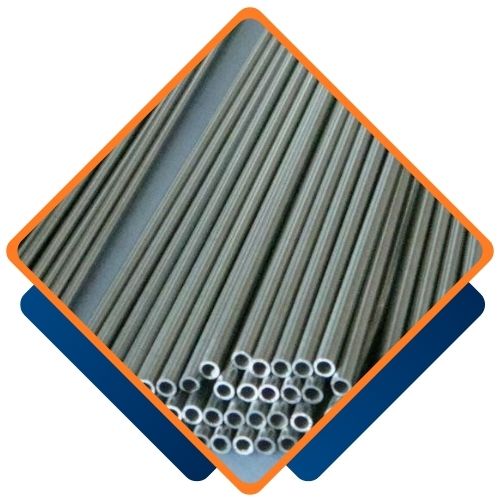

Tube Range : 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A269 / ASTM SA269

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes

| SS | 316TI |

| Ni | 10 – 14 |

| N | 0.10 max |

| Cr | 16 – 18 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.030 max |

| Mo | 2.00 – 3.00 |

| Grade | 316TI |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 35 |

| Hardness | |

| Rockwell B (HR B) max | 75 |

| Brinell (HB) max | 205 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choose Stainless Steel 316Ti Welded Tubing from Aman Pipes and Tubes for exceptional corrosion resistance, superior strength and excellent durability. Ideal for a variety of industrial applications it provides outstanding performance in harsh environments. With precision manufacturing and quality assurance, we ensure reliable and durable tubing solutions.

Aman Pipes and Tubes is the largest supplier of Stainless Steel 316Ti Welded Tubing in Hyderabad, India. Known for its high-quality products. We offer superior corrosion resistance, strength, and durability. Trusted by industries worldwide they provide reliable precision-engineered tubing for various applications and project needs.

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

| SS 316TI | S31635 | 1.4571 | SUS 316TI | Z6CNDT17‐12 | 320S31 | 08Ch17N13M2T | X6CrNiMoTi17-12-2 |

Yes, Aman Pipes and Tubes offer large custom designs for Stainless Steel 316Ti Welded Tubing. With design, wall thickness and length. Their adjustable options ensure the tubing meets specific application requirements. This flexibility makes it more efficient and reliable for different industries and environments. For more details, contact us at sales@amanpipesandtubes.co.in.

| Specific Heat (0-100°C) | Thermal Conductivity | Thermal Expansion | Modulus Elasticity | Electrical Resistivity | Density |

| 500 | 14.6 | 16.5 | 193 | 7.4 | 7.99 |

| J.kg-1.°K-1 | W.m -1.°K-1 | mm/m/°C | GPa | μohm/cm | g/cm3 |

Stainless Steel 316Ti Welded Tubing finds extensive use in applications that demand resistance to high temperatures, chlorides, and corrosive chemicals. It’s commonly utilized in industries such as chemical processing, oil and gas, power generation, heat exchangers, pharmaceutical equipment, and food processing. This tubing is especially well-suited for systems dealing with hot organic and inorganic acids, particularly in welded assemblies where sensitization could be an issue. The titanium stabilization helps maintain corrosion resistance post-welding, making it ideal for exhaust systems, flue gas cleaning, and furnace components. With its excellent weldability, strength, and oxidation resistance, it’s a top choice for demanding applications.

©2024 Aman Pipes and Tubes . All Rights Reserved.