Home > Stainless Steel > Stainless Steel 316Ti Heat Exchanger Tubing

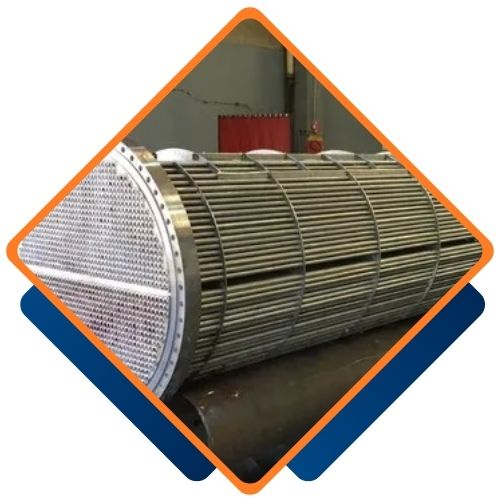

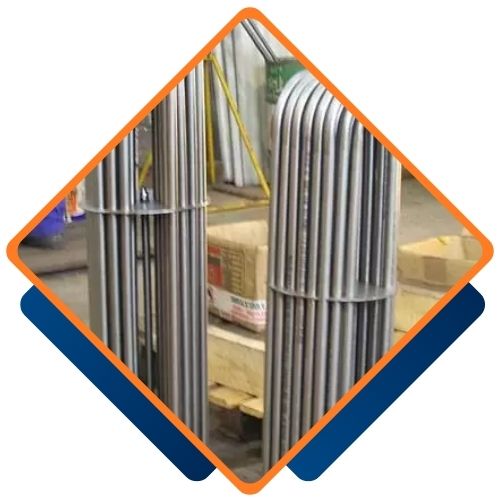

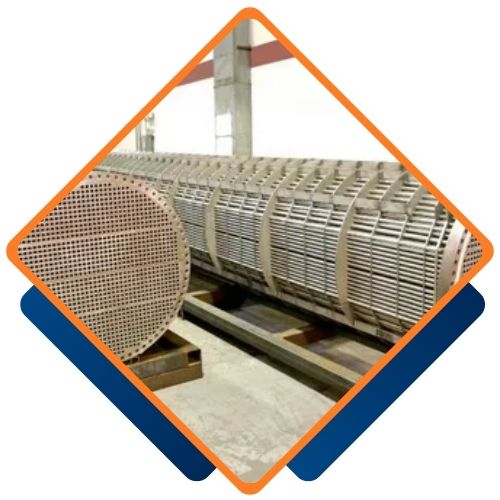

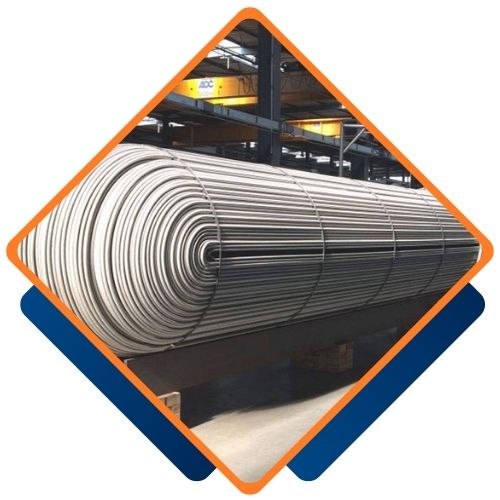

Aman Pipes and Tubes, situated in Hyderabad, India, is a reliable manufacturer and supplier of high-quality Stainless Steel 316Ti Heat Exchanger Tubing. The company, being quality-conscious and precise, provides long-lasting tubing solutions that are designed to function effectively in high-temperature as well as corrosive settings. Their 316Ti tubing is titanium-stabilized to make it highly resistant to intergranular corrosion, particularly following exposure to high temperatures. Aman Pipes and Tubes strives to provide products meeting international standards and customer requirements in various industries, making them a first choice for critical process and heat exchanger applications.

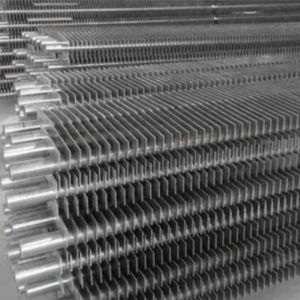

Stainless Steel 316Ti Heat Exchanger Tubing is an austenitic alloy with chromium (16–18%), nickel (10–14%), molybdenum (2–3%), and stabilization by titanium (0.5% max). The addition of titanium enhances high-temperature stability and corrosion resistance. It has a tensile strength of approximately 515 MPa, yield strength of 205 MPa, and elongation of 35%. The alloy has good creep, stress-rupture, and tensile strength at high temperatures. The density of the alloy is 8.0 g/cm³, and it has good weldability and formability and is therefore best suited for challenging heat exchanger systems.

Range : 10 mm OD to 50.8 mm OD

Outer Diameter : 6.00 mm to 101.60 mm

Wall Thickness : 0.70 mm to 8.00 mm

Length : up to 20 m (65.62 ft) Length & Customed Required Length

Specifications : ASTM A 213, A 268, A 269, A 789, Equivalent to ASME, EN, JIS Etc.

| Element | SS 316TI |

| C | 0.08 max |

| Mn | 2.0 max |

| Si | 0.75 max |

| P | 0.045 max |

| S | 0.030 max |

| Cr | 16.00 – 18.00 |

| Mo | 2.00 – 3.00 |

| Ni | 10.00 – 14.00 |

| Fe | 68.395 min |

| Element | SS 316TI |

| Density | 8.0 g/cm3 |

| Melting Point | 1399 °C (2550 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 316Ti Heat Exchanger Tubing from Aman Pipes and Tubes ensures high-quality materials and precise manufacturing standards. Aman Pipes and Tubes is known for delivering reliable tubing with superior corrosion resistance and durability, specifically designed to withstand high-temperature environments. The company offers exceptional customer support, timely delivery, and custom solutions to meet diverse project needs. Their commitment to quality and strict adherence to industry standards make them a trusted choice for heat exchanger tubing, ensuring long-lasting performance and reduced maintenance costs.

Aman Pipes and Tubes, one of the largest suppliers of Stainless Steel 316Ti Heat Exchanger Tubing in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 316Ti Heat Exchanger Tubing to meet your specific requirements. Our team at Aman Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@amanpipesandtubes.co.in.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316TI | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17‐123 | X6CrNiMoTi17-12-2 |

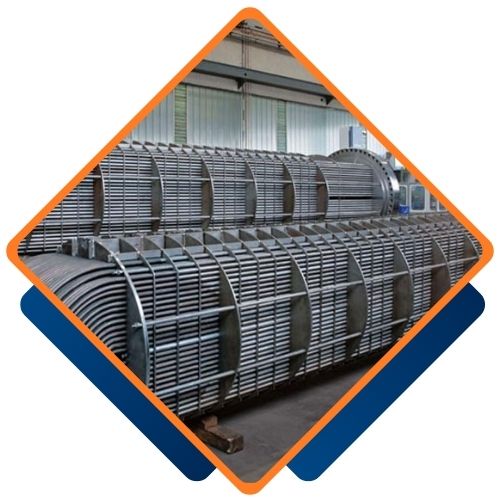

Stainless Steel 316Ti Heat Exchanger Tubing finds extensive applications in industrial sectors that require high-performance corrosion resistance and high-temperature capability. Examples of where these are used include chemical processing, oil and gas refining, electricity generation, and manufacture of pharmaceuticals. The tubing is perfectly suited for use in heat exchangers, condensers, superheaters, and boilers subject to aggressive environments and high pressure. Its application against oxidation and intergranular corrosion enables it to run continuously in high-temperature areas. It is also used in maritime use and food processing facilities where cleanliness, durability, and corrosion resistance are required.

©2024 Aman Pipes and Tubes . All Rights Reserved.