Home > Stainless Steel > Stainless Steel 316H Electropolished Pipes

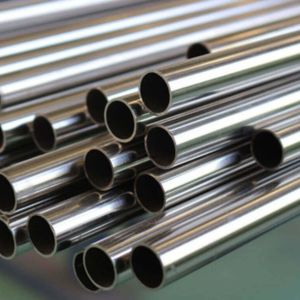

Aman Pipes and Tubes, a reputable manufacturer and supplier based in Hyderabad, India, focuses on delivering top-notch Stainless Steel 316Ti Electropolished Pipes that are designed to meet the strict demands of hygiene-sensitive and corrosive settings. Crafted from titanium-stabilized austenitic stainless steel (316Ti), these pipes undergo a sophisticated electropolishing process that results in a smooth, ultra-clean, and corrosion-resistant finish. With precise dimensions and a superior surface quality that adheres to international standards, Aman Pipes and Tubes guarantees optimal performance in industries such as pharmaceuticals, biotechnology, food processing, and chemical handling, where purity and contamination resistance are crucial.

Stainless Steel 316Ti Electropolished Pipes consist of about 16–18% chromium, 10–14% nickel, and 2–3% molybdenum, with titanium stabilization for enhanced corrosion resistance. The electropolishing technique effectively eliminates surface impurities, minimizing micro-crevices and boosting cleanliness. These pipes boast a tensile strength of around 515 MPa, a yield strength of 205 MPa, and impressive ductility with approximately 35% elongation. They are highly resistant to oxidation and intergranular corrosion, particularly at high temperatures, while maintaining their mechanical strength and surface integrity in chemically aggressive and hygienically demanding environments.

| Electropolished Pipe Standard | ASTM A269 / ASME SA269 |

| Electropolished Pipe Dimension | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Seamless Electropolished Pipe Sizes | 1 / 2″ NB – 16″ NB |

| Welded Electropolished Pipe Sizes | 1 / 2″ NB – 24″ NB |

| Electropolished Pipe Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Electropolished Pipes available Ex-stock |

| Electropolished Pipe Manufacturing Process | Seamless / Welded / ERW / Fabricated / CDW / 100% X Ray Welded |

| Stainless Steel Electropolished Pipe Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Electropolished Pipe Length | Single Random, Double Random, Standard & Cut length |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Electropolished Pipes, Finish as per customer Requirements |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Aman Pipes and Tubes, a leading manufacturer and supplier of Stainless Steel 316H Electropolished Pipes in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubing suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us a trusted choice for regional products.

| STANDARD | WERKSTOFF NR. | UNS |

| SS 316H | 1.4919 | S31609 |

We offer custom sizes for Stainless Steel 316H Electropolished Pipes to meet your specific needs. Our dedicated team at Aman Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@amanpipesandtubes.co.in.

Stainless Steel 316Ti Electropolished Pipes find extensive use in sectors where hygiene, corrosion resistance, and a contaminant-free surface are vital. Key applications include pharmaceutical manufacturing, biotechnology, food and beverage processing, semiconductor fabrication, and cleanroom environments. These pipes are perfect for transporting ultra-pure fluids and gases, ensuring minimal contamination and facilitating easy sterilization. Their smooth interiors help reduce friction, making them an excellent choice for a variety of demanding applications.

©2024 Aman Pipes and Tubes . All Rights Reserved.