Home > Stainless Steel > Stainless Steel 316 and 316L ERW Pipes

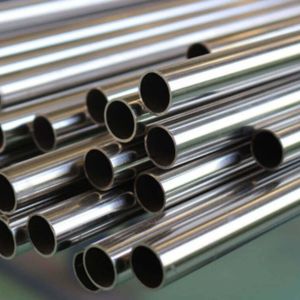

Aman Pipes and Tubes, based in Hyderabad, India, has built a solid reputation for manufacturing and supplying top-notch Stainless Steel 316 and 316L ERW Pipes. These Electric Resistance Welded pipes are celebrated for their outstanding corrosion resistance, impressive strength, and excellent weldability. Offered in a variety of dimensions and specifications, our 316/316L ERW pipes are perfect for both structural and pressure applications, even in tough environments. Thanks to our advanced production methods and rigorous quality control, Aman Pipes and Tubes delivers durable, precise, and cost-effective pipe solutions for industries like petrochemical, pharmaceutical, food processing, and marine sectors, both in India and internationally.

Stainless Steel 316 ERW Pipes are composed of 16–18% chromium, 10–14% nickel, and 2–3% molybdenum, which significantly boosts their resistance to pitting and crevice corrosion. The 316L variant, with its lower carbon content, offers enhanced weldability and better resistance to intergranular corrosion. These pipes showcase a tensile strength of 515 MPa, yield strength of 205 MPa, and an elongation of 40%. The ERW process ensures smooth finishes and uniform thickness. Both grades maintain high strength and exceptional corrosion resistance, particularly in environments rich in chlorides and acids.

Specifications : ASTM A312 / ASME SA312

Dimensions : ASTM, ASME and API

Size : 8″ NB to 24″ NB

Wall Thickness : 0.5 to 150mm Thick

Schedules : SCH 5S, 10S,10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160 & XXS

Length : Single Random, Double Random & Required Length

Form : Round, Square, Rectangular, Hydraulic Pipes

End : Plain end, Bevelled end

Type : Electric Resistance Welded

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 1.0 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 316 and 316L ERW Pipes from Aman Pipes and Tubes guarantees excellent corrosion resistance, high strength, and durability. Designed for diverse industrial applications, it delivers reliable performance in tough environments while maintaining competitive pricing for cost-effective solutions.

Aman Pipes and Tubes, a leading manufacturer and supplier of Stainless Steel 316 and 316L ERW Pipes in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubing suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us a trusted choice for regional products.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 316 | S31600 | 304S11 | 58E | 1.4401 | X5CrNiMo17-12-2 | 2347 | SUS 316 |

| 316L | S31603 | 304S11 | 58E | 1.4436 | X3CrNiMo17-13-3 | 2348 | SUS 316L |

We offer custom sizes for Stainless Steel 316 and 316L ERW Pipes to meet your specific needs. Our dedicated team at Aman Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@amanpipesandtubes.co.in.

Stainless Steel 316 and 316L ERW Pipes are commonly found in industries where high corrosion resistance and hygiene are paramount. They are extensively used in chemical and petrochemical processing, food and beverage, pharmaceutical, marine, and architectural applications. These pipes excel at transporting corrosive fluids and gases, and they are also utilized in heat exchangers, pipelines, and structural components. The 316L variant is particularly favored for welded structures, as it effectively prevents carbide precipitation. Their strength, durability, and ease of fabrication make them the go-to choice for projects that demand high performance and reliability.

©2024 Aman Pipes and Tubes . All Rights Reserved.