Home > Stainless Steel > Stainless Steel 310/310S Heat Exchanger Tubing

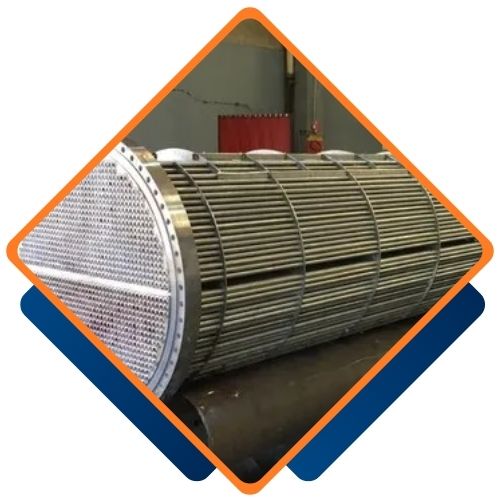

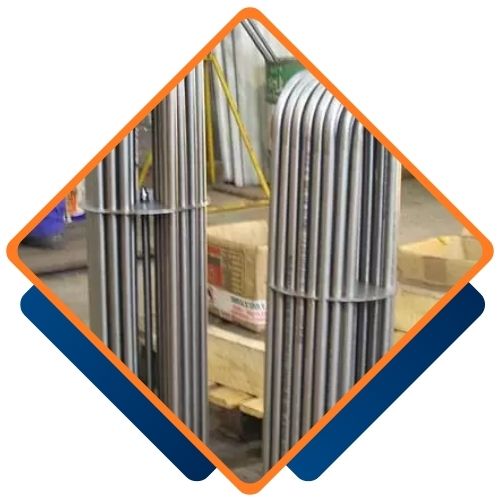

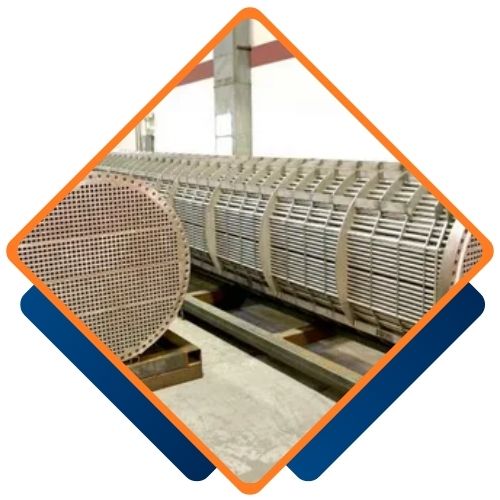

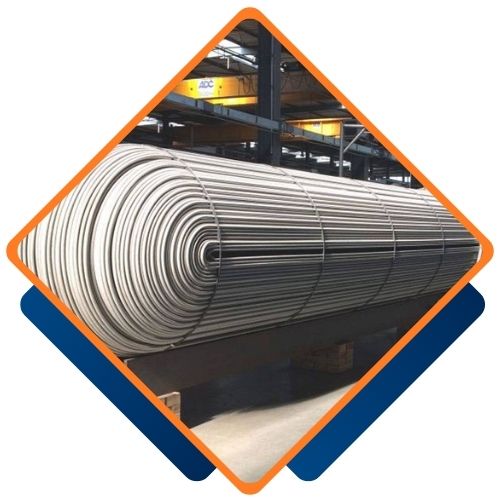

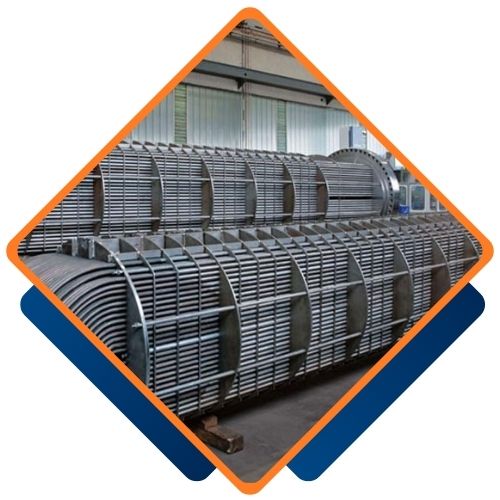

Aman Pipes and Tubes, based in Hyderabad, India, has earned a solid reputation as a reliable manufacturer and supplier of Stainless Steel 310/310S Heat Exchanger Tubing. These top-notch tubes are specifically crafted for applications that demand exceptional resistance to high temperatures and corrosive environments. The company is committed to delivering products that not only meet international standards but also provide outstanding performance. You’ll find Stainless Steel 310/310S heat exchanger tubing in various industries, including power generation, petrochemical, and chemical processing. Aman Pipes and Tubes guarantees superior reliability, strength, and longevity in all their heat exchanger tubing products, making them a perfect fit for critical applications.

Stainless Steel 310/310S Heat Exchanger Tubing is composed of 25-27% Chromium and 19-22% Nickel, with a low carbon content (<0.08%) that enhances its weldability and resistance to sensitization. This alloy is known for its remarkable oxidation and corrosion resistance at high temperatures, making it an excellent choice for heat exchangers. The tubing boasts a tensile strength of 520 MPa, a yield strength of 205 MPa, and an elongation of 40%. It retains good mechanical properties even at elevated temperatures, ensuring durability and resistance to corrosion in challenging conditions.

Range : 10 mm OD to 50.8 mm OD

Outer Diameter : 6.00 mm to 101.60 mm

Wall Thickness : 0.70 mm to 8.00 mm

Length : up to 20 m (65.62 ft) Length & Customed Required Length

Specifications : ASTM A 213, A 268, A 269, A 789, Equivalent to ASME, EN, JIS Etc.

| Element | SS 310 | SS 310S |

| C | 0.015 max | 0.08 max |

| Mn | 2.0 max | 2.0 max |

| Si | 0.15 max | 1.00 max |

| P | 0.020 max | 0.045 max |

| S | 0.015 max | 0.030 max |

| Cr | 24.00 – 26.00 | 24.00 – 26.00 |

| Mo | 0.10 max | 0.75 max |

| Ni | 19.00 – 21.00 | 19.00 – 21.00 |

| Fe | 54.7 min | 53.095 min |

| Element | SS 310/310S |

| Density | 7.9 g/cm3 |

| Melting Point | 1402 °C (2555 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 40 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 310/310S Heat Exchanger Tubing from Aman Pipes and Tubes ensures high-quality materials that meet rigorous industry standards. Our tubing offers exceptional resistance to corrosion and high temperatures, making it ideal for demanding applications. We provide a wide range of sizes and specifications to meet diverse project requirements. With advanced manufacturing processes and stringent quality control measures, our products guarantee reliability and performance. Additionally, our dedicated customer service team is committed to supporting you throughout the purchasing process, ensuring a seamless experience. Trust Aman Pipes and Tubes for durable and efficient heat exchanger solutions.

Aman Pipes and Tubes, one of the largest suppliers of Stainless Steel 310/310S Heat Exchanger Tubing in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 310/310S Heat Exchanger Tubing to meet your specific requirements. Our team at Aman Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@amanpipesandtubes.co.in.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | – | X8CrNi25-21 |

Stainless Steel 310/310S Heat Exchanger Tubing is extensively utilized in industries that rely on dependable heat exchange systems under high-temperature conditions. You’ll often find it in power plants, petrochemical refineries, chemical processing units, and furnaces where effective heat transfer and corrosion resistance are crucial. This tubing is also employed in heat exchangers, boilers, and gas coolers, where its outstanding resistance to oxidation and corrosion at elevated temperatures guarantees long-lasting performance. Its adaptability in managing aggressive environments makes it a go-to choice for many applications.

©2024 Aman Pipes and Tubes . All Rights Reserved.