Home > Stainless Steel > Stainless Steel 309 Pipes

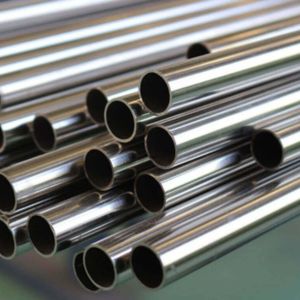

Aman Pipes and Tubes stands out as a top-notch manufacturer and supplier of Stainless Steel 309 Pipes, proudly based in Hyderabad, India. Known for their commitment to quality and reliability, this company specializes in high-performance stainless steel piping solutions that are perfect for high-temperature and corrosive settings. Their Stainless Steel 309 pipes are expertly crafted to endure elevated temperatures and resist oxidation, making them ideal for tough industrial tasks. With cutting-edge manufacturing technology and strict quality control, Aman Pipes and Tubes caters to essential industries like chemical processing, power generation, and furnace construction, providing durable and cost-effective solutions that align with international standards.

Stainless Steel 309 Pipes are made from high-alloy austenitic stainless steels, featuring about 22–24% Chromium, 12–15% Nickel, and up to 0.20% Carbon. This unique blend gives them remarkable resistance to oxidation and high-temperature corrosion. These pipes boast impressive mechanical properties, including a minimum tensile strength of 520 MPa, yield strength of 205 MPa, and an elongation of around 40%. The elevated levels of chromium and nickel enhance their strength and stability under high temperatures, while the austenitic structure ensures they remain ductile, tough, and easy to weld, making 309 pipes perfect for extreme heat and industrial uses.

| Pipe Standard | ASTM A312 ASME SA312 / ASTM A358 ASME SA358 |

| Pipe Dimension | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Pipe Sizes | 1 / 2″ NB – 24″ NB |

| Pipe Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Steel Pipe Manufacturing Process | Seamless / Welded / ERW / Fabricated / CDW / 100% X Ray Welded |

| Stainless Steel Pipe Shapes | Hydraulic, Round, Rectangle, Square, Hex, Honed |

| Stainless Steel Pipe Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Pipe Ends | Half Hard, Soft, Hard, Quarter Hard, Spring Hard |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| GRADE | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| SS 309 | 0.2 max | 2 max | 1 max | 0.045 max | 0.03 max | 22-24 | 12-15 |

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|

| SS 309 | 620 min. | 310 min. | 30 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 309 pipes from Aman Pipes and Tubes ensures high quality and durability, as these pipes offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in stainless steel products ensures you receive a top-tier solution tailored to your needs.

Aman Pipes and Tubes, one of the largest suppliers of Stainless Steel 309 pipes in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 309 pipes to meet your specific requirements. Our team at Aman Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@amanpipesandtubes.co.in.

Stainless Steel 309 Pipes find their place in a variety of high-temperature industrial applications thanks to their exceptional resistance to oxidation and scaling. They’re frequently used in furnace components, heat exchangers, boilers, and thermal processing systems. These pipes are also well-suited for flue gas systems, refineries, incinerators, and kilns, where thermal stress and corrosion are significant concerns. In the chemical and petrochemical sectors, they handle hot corrosive fluids and gases with ease. Plus, 309 pipes are utilized in aerospace applications, showcasing their versatility and reliability in demanding environments.

©2024 Aman Pipes and Tubes . All Rights Reserved.