Home > Nickel Alloy > Nickel Alloy Instrumentation Tubing

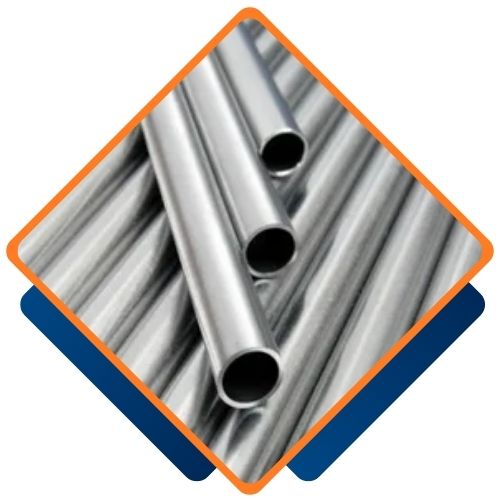

Aman Pipes and Tubes, Hyderabad, India, is a well-known manufacturer and supplier of high-quality Nickel Alloy Instrumentation Tubing. Standing firm in dedication to precision engineering and material quality, the company provides tubing solutions that satisfy the stringent requirements of different industrial uses. Aman Pipes and Tubes is a specialist in delivering corrosion-resistant, high-performance nickel alloy tubes specifically designed for instrumentation systems. Supported by state-of-the-art manufacturing facilities and rigorous quality checks, the company has garnered a reputation of trust among customers in petrochemical, oil & gas, chemical, and power generation industries both domestically and overseas.

Nickel Alloy Instrumentation Tubing is usually made of nickel (60–75%), chromium (15–21%), iron, molybdenum, and traces of copper and manganese. This mixture provides excellent resistance to corrosion and elevated temperatures. Mechanically, the tubing has high tensile strength (to 850 MPa), yield strength (to 450 MPa), and elongation of to 30%. It is also resistant to durability and integrity under harsh pressure and heat conditions. The tubing also boasts fine fatigue endurance, making it suitable for heavy-duty industrial instrumentation systems that need sustained performance and reliability.

| Nickel Alloy Specification | ASTM B163/ ASME SB163, ASTM B725/ ASME SB725 |

| Nickel Alloy Grades | UNSN08811, UNSN08825, UNSN08020, UNSN10276 |

| Nickel Alloy Type | SEAMLESS / WELDED / ERW / EFW / COLD DRAW / HOT FINISH / COLD FINISH |

| Nickel Alloy Outer Diameter Size | SEAMLESS – 1/2″ NB TO 18″ NB WELDED / ERW- 1″ NB TO 16″ NB EFW – 8″ NB TO 110″ NB |

| Nickel Alloy Wall Thickness | Schedule 10 To Schedule 160 (3 mm to 100 mm Thickness) |

| Nickel Alloy Length | 01 Meter to 12.5 Meters, Single Random Length, Double Random Length And Customize Size. |

| Nickel Alloy Ends | Plain Ends / Beveled Ends |

| Nickel Alloy Delivery Conditions | As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered, Cold Draw, Bright Annealed |

| Nickel Alloy Coating | Electropolish, Mechanical Polish, Satin Finish, Passivated |

| Nickel Alloy Other Testing | Product Analysis, Transverse Tension Test, Flattening Test, Etching Test, Radiographic Examination, Stabilizing Heat Treatment, Intergranular Corrosion Test, Weld Decay Test, Magnetic Particle Detection, Grain Size Test, NACE 0175, Dual Grade, PWHT (POST WELD HEAT TREATMENT), Flare Test, Bend Test, Hardness Test, Tensile Test etc |

| Nickel Alloy Dimension | All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM and ASME |

| Nickel Alloy Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| Nickel Alloy Packaging | Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| Nickel Alloy Shipment & Transportation | By Road – Truck / Train, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| Nickel Alloy Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

| Ni % | Cu % | Fe% | Mn % | C % | Si % | S % |

| 63.0 min | 28.0-34.0 | 2.50 max | 2.00 max | 0.30 max | 0.50 max | 0.024 max |

| Tensile Strength, Mpa | Yield Strength, MPa | Elongation, % | Hardness, HRB | |

| 483 min | 193 min | 35 min | – | +A |

| 586 min | 379 min | 15 min | 75 max | SR |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Nickel Alloy Instrumentation Tubing from Aman Pipes and Tubes ensures high quality and durability, as this tubing offers excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in nickel alloy products ensures you receive a top-tier solution tailored to your needs.

Aman Pipes and Tubes, one of the largest suppliers of Nickel Alloy Instrumentation Tubing in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us the go-to choice for nickel alloy products in the region.

Yes, we offer custom sizes for Nickel Alloy Instrumentation Tubing to meet your specific requirements. Our team at Aman Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@amanpipesandtubes.co.in.

Nickel Alloy Instrumentation Tubing is extensively utilized in industries demanding safe and precise fluid or gas regulation in harsh conditions. Nickel Alloy Instrumentation Tubing is important for utilization in petrochemical plants, offshore oil platforms, chemical plants, and thermal and nuclear power plants. The tubes are vital to be used in exact instrumentation purposes like pressure gauge measurement, flow regulation, and sample transmission. Their resistance to corrosion and heat makes them suitable for marine, aerospace, and pharmaceutical applications where equipment should consistently perform under severe chemical attack, high pressure, and varying temperature, ensuring system safety and operational efficiency.

©2024 Aman Pipes and Tubes . All Rights Reserved.