Home > Nickel Alloy > Nickel Alloy Boiler Tubing

Aman Pipes and Tubes is a trusted manufacturer and supplier of premium nickel alloy boiler tubing based in Hyderabad, India. Renowned for quality, durability, and precision engineering, the company caters to a diverse clientele across power generation, petrochemical, and industrial sectors. With a strong focus on meeting international standards, Aman Pipes and Tubes ensures its nickel alloy boiler tubing offers superior resistance to high temperatures and corrosion. Backed by advanced manufacturing facilities and a skilled workforce, the company is committed to delivering reliable and cost-effective tubing solutions that meet critical industry requirements.

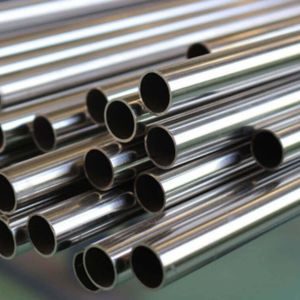

Nickel alloy boiler tubing typically contains high nickel content (60–70%) along with chromium, iron, molybdenum, and small amounts of manganese and silicon. These alloys offer exceptional strength, oxidation resistance, and thermal stability. Mechanical properties include tensile strength ranging from 500 to 800 MPa and yield strength of 200 to 400 MPa, depending on the grade. The tubing also offers excellent elongation (up to 45%) and hardness. Its superior performance in elevated temperatures and corrosive environments makes it ideal for demanding boiler and heat exchanger applications.

| Nickel Pipe sizes range | 1/8”NB to 30”NB (Nominal Bore Diameter, ie the inner diameter of the pipe) |

| Manufacturer of | Seamless, Welded, Electric Resistance Welded (ERW), Fabricated, or LSAW |

| Form of | Round, Hydraulic, Rectangular, or Square |

| Marking | All Nickel Alloy pipes & tubes are marked as: Manufacturer Name, Standard, Grade, Thickness, OD, Length, Heat No. (Or according to the customer’s request.) |

| Pipe Schedule | SCH5, SCH10, SCH10S, SCH20, SCH30, SCH40, SCH40S, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Pipe End | POE, TOE, TBE, BOE, BOE, PBE, BLE, BSE, BBE, BE, Plain End, Beveled End, and Treaded |

| Nickel Alloy Tubes | Ni | C | Mo | Mn | Si | Fe | P | S | Cu | Cr |

|---|---|---|---|---|---|---|---|---|---|---|

| Alloy 200 Tube | 99.0 min | 0.15 max | – | 0.35 max | 0.1 max | 0.4 max | – | 0.01 max | 0.25 max | – |

| Alloy 201 Tube | Balance | 0.15 max | – | 0.35 max | 0.35 max | 0.40 max | – | 0.01 max | 0.25 max | – |

| Nickel Based Alloys | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| Alloy 200/ 201 Tube | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 21500 , MPa – 148 | Psi – 67000 , MPa – 462 | 45 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Nickel Alloy Boiler Tubing from Aman Pipes and Tubes ensures high quality and durability, as these tubing offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in nickel alloy products ensures you receive a top-tier solution tailored to your needs.

Aman Pipes and Tubes, one of the largest suppliers of Nickel Alloy Boiler Tubing in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for nickel alloy products in the region.

Yes, we offer custom sizes for Nickel Alloy Boiler Tubing to meet your specific requirements. Our team at Aman Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@amanpipesandtubes.co.in.

Nickel alloy boiler tubing is widely used in industries that demand high-temperature and high-pressure resistance, including power plants, oil refineries, chemical processing units, and marine engineering. It plays a critical role in boiler systems, heat exchangers, condensers, and superheaters, ensuring safe and efficient heat transfer. Its resistance to scaling, oxidation, and corrosion makes it ideal for environments with harsh chemicals or fluctuating thermal conditions. The tubing is also employed in nuclear reactors and aerospace engineering where material performance is crucial. Its versatility and durability make it a preferred choice for long-lasting, high-performance applications.

©2024 Aman Pipes and Tubes . All Rights Reserved.