Home > Nickel Alloy > Nickel Alloy 200 Tubing

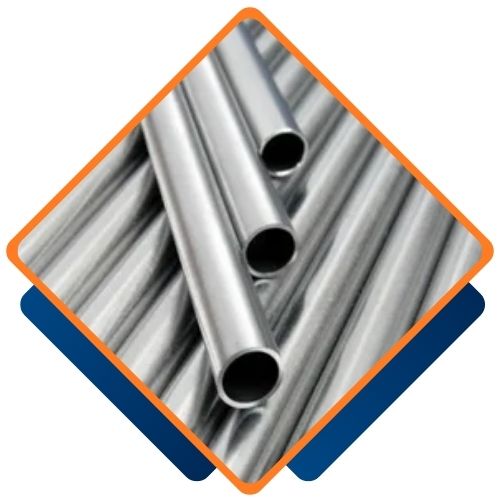

Aman Pipes and Tubes, located in Hyderabad, India, stands out as a premier manufacturer and supplier of high-quality Nickel Alloy 200 Tubing. This tubing is celebrated for its excellent thermal and electrical conductivity, impressive corrosion resistance, and robust mechanical strength, making it perfect for a variety of industrial applications. At Aman Pipes and Tubes, the focus is on maintaining top-notch production standards while offering tailored solutions for sectors like chemical processing, electronics, and aerospace. With a strong commitment to innovation and dependability, the company has become a trusted partner for all Nickel Alloy 200 Tubing needs.

Nickel Alloy 200 Tubing is mainly made up of pure nickel (at least 99%), along with small amounts of iron, manganese, and copper. This unique blend provides remarkable resistance to corrosion, especially in environments with alkalis, acids, and neutral salts. The alloy boasts a tensile strength of around 462 MPa and a yield strength of 148 MPa, with a minimum elongation of 40%. It retains excellent mechanical properties even at elevated temperatures, ensuring it remains durable and efficient in tough conditions. Its thermal and electrical conductivity further boosts its appeal for specialized uses.

| ASTM B161 Alloy 200 Tubing Standards | ASTM B161/ ASME SB161, ASTM B725/ ASME SB725 |

|---|---|

| ASTM B161 Alloy 200 Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| ASTM B161 Alloy 200 Welded Tube Size | 6.35 mm OD To 152 mm OD |

| ASTM B725 Nickel 200 Tubing Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Inconel WERKSTOFF NR. 2.4066 Tube wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Inconel UNS N02200 Tubing Length | Single Random, Double Random, Standard & Cut length Tube |

| Inconel WERKSTOFF NR. 2.4066 Tubing Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| Form | ‘U’ bent, Hollow, Hydraulic, LSAW, Boiler, Straight Tube, Tube Coil, Round, Rectangular, Square Etc |

| Types of Nickel NW 2200 Tubing | Seamless, ERW, EFW, Welded, Fabricated Tube / Tubing |

| Nickel NW 2200 Tube End | Plain End, Beveled End, Treaded Tube |

| Marking | All ASTM B161 Nickel 200 Tubing are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Application & uses of Nickel 200 Tube | Oil Tube, Gas Tube, Fluid Tube, Boiler Tube, Heat exchanger Tube, |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Specialize in | ASTM B161 Nickel 200 Capillary Tube & Other Odd Size Nickel NCF 200 Heat Exchanger & Condenser Tube |

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| Nickel 200 | Ni | C | Mo | Mn | Si | Fe | P | S | Cu | Cr |

| 99.0 Min | 0.15 Max | – | 0.35 Max | 0.1 Max | 0.4 Max | – | 0.01 Max | 0.25 Max | – |

| Nickel Alloy 200 | ||

|---|---|---|

| Properties | Metric | Imperial |

| Tensile strength (annealed) | 462 MPa | 67000 psi |

| Yield strength (annealed) | 148 MPa | 21500 psi |

| Elongation at break (annealed prior to test) | 45% | 45% |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

| Density | 8.902gm/cc |

|---|---|

| Melting Point | 1453 oC |

| Boiling Point | 2732 oC |

| Thermal Conductivity | 0.909 W/cm/K @ 298.2K |

| Electrical Resistivity | 6.84 microhm-cm @ 20 |

| Electronegativity | 1.8 Paulings |

| Specific Heat | 0.106 Cal/g/ K @ 25 |

| Heat of Vaporization | 91.0 K-Cal/gm atom at 2732 oC |

| Heat of Fusion | 4.20 Cal/gm mole |

Choosing Nickel Alloy 200 Tubing from Aman Pipes and Tubes ensures high quality and durability, as these tubing offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in nickel alloy products ensures you receive a top-tier solution tailored to your needs.

Aman Pipes and Tubes, one of the largest suppliers of Nickel Alloy 200 Tubing in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for nickel alloy products in the region.

| Types of Nickel 200 Tube | Out diameter (OD) | Wall thickness | Length |

|---|---|---|---|

| NB Sizes (in stock) | 1/8” ~ 8” | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Upto 6 Meters |

| Nickel 200 Seamless Tube (Custom Sizes) | 5.0mm ~ 203.2mm | As per requirement | Upto 6 Meters |

| Nickel 200 Welded Tube (in Stock + Custom Sizes) | 5.0mm ~ 1219.2mm | 1.0 ~ 15.0 mm | Upto 6 Meters |

Yes, we offer custom sizes for Nickel Alloy 200 Tubing to meet your specific requirements. Our team at Aman Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@amanpipesandtubes.co.in.

Nickel Alloy 200 Tubing finds its place in industries where top-notch corrosion resistance and conductivity are crucial. It’s perfect for heat exchangers, chemical processing equipment, and caustic soda production. Additionally, this tubing is utilized in the electronics sector for anode and cathode materials, in aerospace for high-temperature applications, and in marine settings for desalination plants. Its ability to endure extreme conditions while maintaining performance over time makes it a go-to choice for critical operations across various industrial fields.

©2024 Aman Pipes and Tubes . All Rights Reserved.