Home > Incoloy > Incoloy 825 Tubing

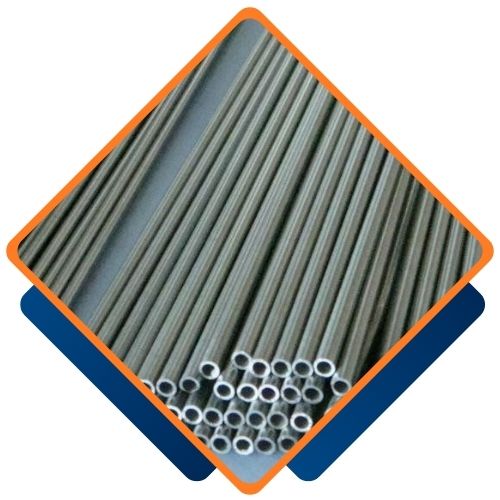

Premium-grade Incoloy 825 tubing is available from Aman Pipes and Tubes, a reputable manufacturer and supplier with headquarters in Hyderabad, India. This tubing is made for high-performance applications in corrosive and hot environments. For demanding industrial applications, Incoloy 825 tubing is the best choice due to its exceptional resistance to acids, oxidation, and stress-corrosion cracking. Aman provides tubing solutions that meet international standards, emphasising accuracy, longevity, and client satisfaction. Aman Pipes and Tubes serves a wide range of customers in sectors including chemical processing, marine, power generation, and oil and gas exploration, supported by state-of-the-art facilities and a knowledgeable workforce.

Incoloy 825 tubing is made primarily of nickel, chromium and steel, with additions of molybdenum. Copper and titanium to enhance corrosion and oxidation resistance These unique materials provide excellent protection against pitting and stress corrosion cracking in violent environments. Mechanically Incoloy 825 tubing exhibits high tensile strength, excellent ductility, and superior heat resistance. Benefits include excellent durability under acid corrosive conditions, making it ideal for applications in the chemical industry, oil and gas and electricity generation, as well as providing incident maintenance floor and longevity.

| Standard Specification | ASTM B163 UNS N08825, ASTM B516 UNS N08825 / ASME SB 163, SB 516 Seamless Superheater, Condenser, Hydraulic, Boiler and Heat-Exchanger Tubes |

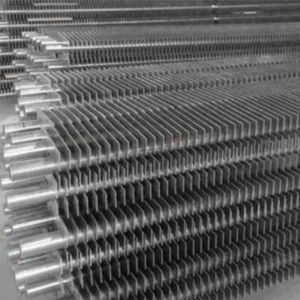

| Shapes | Incoloy 825 Round, Rectangular, Square, Hydraulic, Straight, “U” Shape, Coiled, Honed Tubes, Pan Cake Coils |

| Manufacturing Type | Seamless / ERW / Welded / Fabricated / CDW / CDS / DOM / CEW / 100% X Ray Welded |

| Delivery Condition | Annealed and Pickled (AP), Polished, Bright Annealed (BA), Cold Drawn, MF |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXH, SCH XXS, SCH XS |

| Standard | SUS, JIS, AISI, ASTM, GB, DIN, EN |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded 825 Incoloy Tube |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting, Moulding |

| Technique | Incoloy Alloy 825 Cold drawn, Cold rolled, Hot rolled, Extrusion Tube |

| Marking |

|

| Test Certificate |

|

| ASTM B163 Alloy 825 Tubing Packaging | Packed in PE Fabric Bundles or ply wooden box wrapped in plastic or Standard seaworthy export packing or as per customers’ request |

|

Properties |

Metric |

Imperial |

|

|

Thermal expansion co-efficient (at 20-100°C/68-212°F) |

14 µm/m°C |

7.78 µin/in°F |

|

|

Thermal conductivity |

11.1 W/mK |

77 BTU in/hr.ft².°F |

|

| Alloy | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| 825 | 0.05 max | 1.00 max | 0.05 max | 0.03 max | 1.50 – 3.00 | 22.00 min | 38.00 – 46.00 | 19.50 – 23.50 | 0.02 max | 0.06 – 1.20 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Incoloy 825 Tubes from Aman Pipes and Tubes ensures superior quality and durability, offering outstanding corrosion resistance and high strength. Our dedication to delivering exceptional service and reliable products guarantees customer satisfaction across a wide range of industrial applications. With our expertise in Incoloy solutions, you can trust us to provide a top-tier, customized piping solution that meets your specific requirements.

Aman Pipes and Tubes, one of the largest suppliers of Incoloy 825 Tubing in the Hyderabads, India. Offers a wide range of high-quality pipes and tubes designed for various industrial applications. Their extensive inventory and dedication to exceptional service make them a trusted choice for Incoloy products in the region, delivering reliable solutions to meet diverse project requirements.

| Incoloy | Density | Melting Range | Tensile Stress | Yield Stress (0.2%Offset) | Elongation |

| 825 | 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

| ALLOY | WERKSTOFF NR./ DIN | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 825 | 2.4858 | N08825 | NCF 825 | NA 16 | ЭП703 | NFE30C20DUM | NiCr21Mo | XH38BT |

Yes, we provide custom sizes for Incoloy 825 Tubes to meet your specific requirements. At Aman Pipes and Tubes, our team is dedicated to delivering tailored solutions for all your piping and tubing needs. For more information, please contact us at sales@amanpipesandtubes.co.in.

Applications involving harsh chemical environments and high temperatures frequently use Incoloy 825 tubing. It is perfect for handling phosphoric and sulphuric acids in heat exchangers, piping systems, and reactors in the chemical and petrochemical industries. It is used in downhole tubing, gas scrubbing systems, and offshore platforms in the oil and gas industry. Because of its exceptional resistance to corrosion, it is also widely utilised in pollution control devices, marine exhaust systems, and nuclear fuel reprocessing. Incoloy 825 tubing guarantees safe and durable operation in extremely corrosive and thermally demanding environments in waste treatment and power generation facilities.

©2024 Aman Pipes and Tubes . All Rights Reserved.