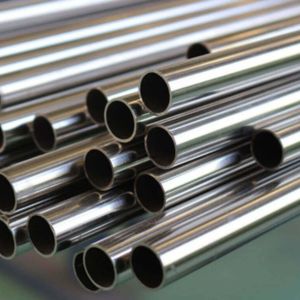

Aman Pipes and Tubes is a reputable manufacturer and supplier of Hastelloy ERW Pipes, proudly based in Hyderabad, India. We focus on providing top-notch, corrosion-resistant piping solutions for a variety of industries, including chemical processing, marine applications, and pollution control. Our Hastelloy Electric Resistance Welded (ERW) Pipes are produced using cutting-edge manufacturing techniques and rigorous quality control measures, ensuring they are strong and durable. With a dedication to excellence, timely delivery, and customer satisfaction, Aman Pipes and Tubes has established itself as a trusted source for high-performance alloy pipes that can endure the toughest operational conditions while delivering reliable service over time.

Hastelloy ERW Pipes are primarily made up of high Nickel content (around 58%), along with varying amounts of Molybdenum (up to 30%), Chromium, Iron, and Cobalt, depending on the specific grade (like C276 or C22). These pipes are known for their outstanding resistance to pitting, stress corrosion cracking, and both oxidizing and reducing environments. In terms of mechanical properties, they boast a tensile strength ranging from 690 to 760 MPa, yield strength around 280 to 350 MPa, and an elongation of about 40%. Additionally, Hastelloy ERW Pipes exhibit excellent ductility, weldability, and structural stability across a broad temperature range.

Specifications : ASTM A619 / ASME SA619

Dimensions : ASTM, ASME and API

Size : 8″ NB to 24″ NB

Wall Thickness : 0.5 to 150mm Thick

Schedules : SCH 5S, 10S,10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160 & XXS

Length : Single Random, Double Random & Required Length

Form : Round, Square, Rectangular, Hydraulic Pipes

End : Plain end, Bevelled end

Type : Electric Resistance Welded

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C22 | Balance | 0.010 max | 12.5-14.5 | 0.50 max | 0.08 max | 2-6 | 0.02 max | 0.02 max | 2.5 max | 20-22.5 | 2.5-3.5 | 0.35 max |

| Hastelloy C276 | Balance | 0.01 max | 15–17 | 1.0 max | 0.08 max | 4–7 | 0.04 max | 0.03 max | 2.5 max | 14.5–16.5 | 3–4.5 | 0.35 max |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Hastelloy C22 | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000, MPa – 690 | Psi – 45000, MPa – 310 | 45 % |

| Hastelloy C276 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choose Hastelloy ERW Pipes from Aman Pipes and Tubes for their exceptional corrosion resistance, high strength, and durability. These pipes are ideal for marine, chemical, and offshore applications, offering long-lasting performance and superior reliability.

Aman Pipes and Tubes is the largest supplier of Hastelloy ERW Pipes in Hyderabad, India, providing top-quality, corrosion-resistant pipes and tubing ideal for marine, industrial, and chemical applications, with reliable delivery and excellent customer service.

| STANDARD | UNS | WNR. | EN | JIS | GOST | OR |

|---|---|---|---|---|---|---|

| Hastelloy C22 | N06022 | 2.4602 | NiCr21Mo14W | NW 6022 | – | – |

| Hastelloy C276 | N10276 | 2.4819 | NiMo16Cr15W | NW 0276 | ХН65МВУ | ЭП760 |

Yes, custom sizes are available for Hastelloy ERW Pipes to meet specific project requirements. These pipes can be tailored for various industrial applications. For more details, contact us at sales@amanpipesandtubes.co.in.

Hastelloy ERW Pipes find extensive use in highly corrosive settings such as chemical processing plants, power generation facilities, marine industries, and waste treatment plants. Their ability to resist acids like hydrochloric, sulfuric, and nitric makes them perfect for applications in reactors, heat exchangers, scrubbers, and pressure vessels. In the pharmaceutical and food sectors, they guarantee contamination-free processing thanks to their non-reactive nature. They are also employed in flue gas scrubbers, pulp and paper bleaching systems, and offshore installations. The exceptional mechanical and anti-corrosive characteristics of Hastelloy ERW Pipes make them essential in critical applications.

©2024 Aman Pipes and Tubes . All Rights Reserved.