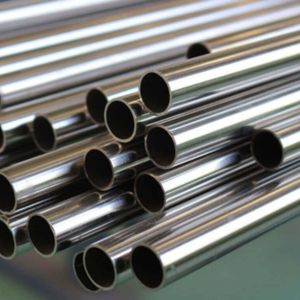

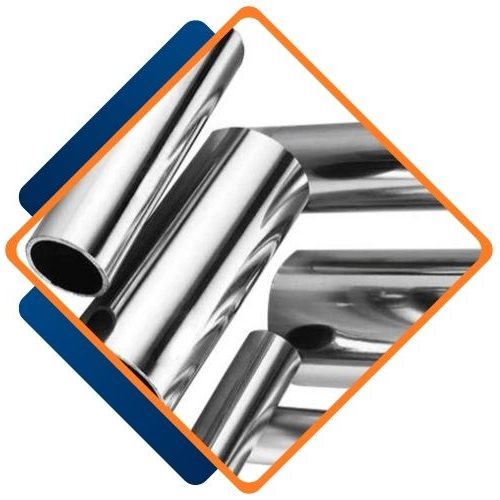

Aman Pipes and Tubes, located in Hyderabad, India, has earned a solid reputation as a reliable manufacturer and supplier of Aluminium Welded Tubing. Known for being lightweight, corrosion-resistant, and incredibly versatile, their products are crafted with a strong focus on quality and innovation. The company takes pride in delivering precision-engineered tubing solutions that cater to the unique needs of various industries. Using cutting-edge techniques, their Aluminium Welded Tubing is built to last, ensuring consistent performance across the board. These tubes are a testament to Aman Pipes and Tubes’ commitment to excellence and customer satisfaction.

The Aluminium Welded Tubing is made from high-grade aluminum alloy, often mixed with elements like magnesium, silicon, and manganese to boost its strength, ductility, and resistance to corrosion. It boasts impressive mechanical properties, including a high strength-to-weight ratio, excellent thermal conductivity, and remarkable weldability. With good fatigue resistance and a smooth finish, these tubes are designed to excel in both structural and fluid-transfer applications. The aluminum material keeps them lightweight without sacrificing durability, making them a dependable choice for a variety of industrial needs.

Standards : ASTM B345, B241, B429 / ASME SB345, SB241, SB429

Temper : T6 T651 T6511

Standard : AMS QQ-A-200/8, AMS QQ-A-200/9, AMS 4160/4161/4172

Size : 8 (1-1/2″ / 1.900″)

Outer Diameter : 1″ through 16″

Length : Double Random, Single Random, Cut Length

Thickness : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

End : Plain End, Beveled End, Threaded

| Alloy | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Others | AI |

| 1100 (min) | 0.35 | 0.25 | 0.01 | 0.01 | 0.05 | 0.01 | 0.020 | Trace | 0.05 (each) | 99.60% |

| 1100 (max) | 0.50 | 0.35 | 0.03 | 0.05 | 0.20 | 0.05 | 0.030 | Trace | 0.15 (total) | remainder |

| 5083 | 0.40 max | 0.40 max | 4.0 / 4.90 | 0.40 / 1.0 | 0.10 max | 0.25 max | 0.15 max | 0.05 / 0.25 | 0.05 max | Bal |

| 6061 | 0.7 | 0.4-0.8 | 0.8-1.2 | 0.15 | 0.15-0.4 | 0.25 | 0.15 | 0.15-0.35 | 0.005/0.15 | Remainder |

| 6068 | 0.50 max | 0.7 – 1.3 | 0.06-1.20 | 0.40-1.00 | 0.10 max | 0.20 max | 0.10 max | 0.25 max | 0.05 max | Bal |

| 7075 min | 2.10 | 1.20 | 5.10 | 0.18 | ||||||

| 7075 max | 0.50 | 0.40 | 2.90 | 0.30 | 2.00 | 6.10 | 0.20 | 0.28 | 0.05 |

| Alloy | Temper | UTS(Mpa) | % Elongation | Tensile Strength | Hardness Brinell | Proof Stress | Yield Strength (PSI) | Shear Strength (PSI) | Brinell Hardness | |||

| Min | Max | 0.5 mm -0.8 mm | 0.81 mm – 1.30 mm | 1.30 mm – above | ||||||||

| 1100 | O | 75 | 110 | 20 | 25 | 29 | ||||||

| H12 | 95 | 130 | 5 | 6 | 7 | |||||||

| H14 | 110 | 145 | 3 | 4 | 5 | |||||||

| H16 | 130 | 165 | 2 | 3 | 4 | |||||||

| H18 | 150 | — | 2 | 2 | 3 | |||||||

| 5083 | 12 Min % | 275 – 350 MPa | 75 HB | 125 Min MPa | ||||||||

| 6061 | – | 45,000 | 12 | 40,000 | 31,000 | 95 | ||||||

| 6082 | 8 | 295 | 95 | – | 240 | – | – | |||||

| 7075 T6, T651 | 11 | 83-572 | 73- 503 | 150 | ||||||||

| 7075 T73, T7351 | 13 | 73-503 | 63-434 | NA | ||||||||

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Aluminium Welded Tubing from Aman Pipes and Tubes ensures you receive top-quality products tailored to your specific requirements. Our tubing is manufactured using advanced techniques and high-grade aluminum alloys, providing exceptional strength and durability. We adhere to stringent quality control standards to guarantee reliability and performance in various applications, including automotive, aerospace, and construction. With a commitment to customer satisfaction, we offer customized solutions, timely delivery, and expert support, making Aman Pipes and Tubes your trusted partner for all your aluminium welded tubing needs.

Aman Pipes and Tubes, one of the largest suppliers of Aluminium Welded Tubing in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Aluminium Welded Tubing to meet your specific requirements. Our team at Aman Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@amanpipesandtubes.co.in.

| Grade | UNS | USA | Japan | France | ISO | WNR | EN | DIN | ISO | BS (OLD) |

| 1100 | A91100 | AA1100 | JIS A1100P | NF 1100 | Al 99.0 Cu. | – | – | – | – | – |

| 6082 | A96082 | AA6082 | – | – | – | 3.2315 | AW-6082 | AlMgSi1 | AlSi1MgMn | HE30 |

| 5083 | A95083 | 5083 | – | – | AlMg4,5Mn0,7 | 3.3547 | AW-AlMg4,5Mn0,7 | AlMg4,5Mn | – | – |

| 6061 | A96061 | AA6061 | – | – | – | 3.3211 | AW-AlMg1SiCu EN AW-6061 | AlMgSiCu | AlMg1SiCu | HE20 |

| 7075 | A97075 | 7075 | 3.4365 | ENAW-AlZn5.5MgCu EN AW-7075 | AlZnMgCu1.5 | AlZn6MgCu | 7075 L95 L96, V95 |

Aluminium Welded Tubing finds its place in numerous industries, including automotive, aerospace, construction, marine, and HVAC systems. Its lightweight and corrosion-resistant characteristics make it perfect for structural components, heat exchangers, and piping systems. In the automotive and aerospace fields, these tubes help improve fuel efficiency by cutting down on weight while still providing strength. They’re also popular in architectural projects, like railings and frames, and in marine applications due to their outstanding resistance to saltwater. Overall, Aluminium Welded Tubing is a versatile and cost-effective solution for tackling modern engineering challenges.

©2024 Aman Pipes and Tubes . All Rights Reserved.