Home > Stainless Steel > Stainless Steel 904L Seamless Pipes

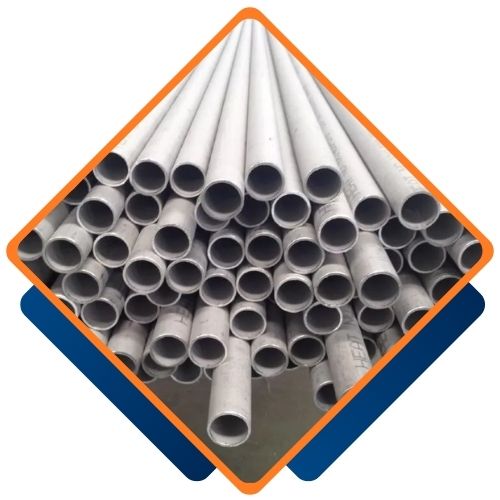

Aman Pipes and Tubes, a Hyderabad, India-based company, is a reliable manufacturer and exporter of Stainless Steel 904L Seamless Pipes to various industrial segments around the world. With our reputation for accuracy engineering, quality control, and customer-focused services, we provide an extensive array of seamless pipes specifically designed to suit highly corrosive applications. Our SS 904L seamless tubes are produced with the latest technology and high-grade raw materials, which guarantee high durability, strength, and performance. We supply these to chemical processing, pharmaceutical, power generation, and marine industries, and adhere strictly to international standards with a delivery schedule ensured on time.

Stainless Steel 904L Seamless Tubes consist mainly of iron, with small percentages of chromium (19-23%), nickel (23-28%), molybdenum (4-5%), and copper (1-2%) for added corrosion resistance. These pipes have very good mechanical properties, such as minimum tensile strength of 490 MPa and minimum yield strength of 220 MPa. The elongation at break is generally 35% or greater, and they possess better toughness even at cryogenic temperatures. The low carbon content in the material also improves weldability and minimizes the chances of intergranular corrosion, thus making it exceptionally fit for corrosive and aggressive environments.

Range : 6NB to 1200NB

Outer Diameter : 1/8″ NPS to 12″ NPS

Thickness : 0.6 mm to 12.7 mm

Schedules : SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS.

Length : Single Random, Double Random & Cut Length

Specifications : ASTM B677 / ASTM SB677

Types : Round, Square, Rectangle, Hydraulic, Honed Tubes

End : Plain End, Beveled End

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | KS | EN |

| SS 904L | N08904 | 1.4539 | SUS 890L | Z2 NCDU 25-20 | 904S13 | STS 317J5L | X1NiCrMoCu25-20-5 |

| Ni | 23 – 28 |

| Cu | 1.00 – 2.00 |

| Cr | 19 – 23 |

| C | 0.20 max |

| Si | 1 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.035 max |

| Mo | 4.00 – 5.00 |

| Grade | 904L |

| Tensile Strength (MPa) min | 490 |

| Yield Strength 0.2% Proof (MPa) min | 220 |

| Elongation (% in 50mm) min | 35 |

| Hardness | |

| Rockwell B (HR B) max | 92 |

| Brinell (HB) max | – |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 904L Seamless Pipes from Aman Pipes and Tubes guarantees exceptional corrosion resistance and high temperature performance. Their pipes are manufactured to exacting standards, ensuring reliability and durability for complex applications. With a focus on customer service, Brydon offers customized solutions and technical support. In addition, the rugged design reduces leakage, making it reliable for a variety of applications.

Aman Pipes and Tubes, one of the largest suppliers of Stainless Steel 904L Seamless Pipes in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 904L | N08904 | 904S13 | – | 1.4539 | X1NiCrMoCuN25-20-5 | 2562 | – |

Yes, we offer custom sizes for Stainless Steel 904L Seamless Pipes to meet your specific requirements. Our team at Aman Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@amanpipesandtubes.co.in.

904L Stainless Steel Seamless Pipes have vast applications in industries that demand exceptional corrosion resistance and structural stability. Their uses include oil and gas, petrochemical, chemical processing, marine engineering fields, where they can resist aggressive chemicals, sulfuric acid, and chloride-containing environments. They are used in heat exchangers, pressure vessels, condenser tubing, and anti-pollution equipment, too. Their high formability, strength, and resistance to pitting and crevice corrosion render them suitable for application in high-temperature and high-pressure systems to provide long service life and reliable operation.

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| 904L | 8000 | 200 | 15 | – | – | 13 | – | 500 | 850 |

©2024 Aman Pipes and Tubes . All Rights Reserved.