Home > Stainless Steel >Stainless Steel 439 Pipes

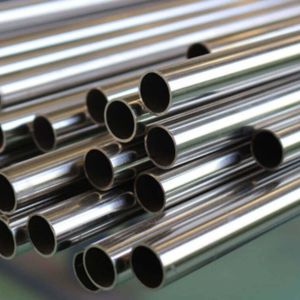

Hyderabad-based Indian company Aman Pipes and Tubes is a quality manufacturer and supplier of high-quality Stainless Steel 439 Pipes. Renowned for reliability, long life, and accuracy engineering, Aman Pipes and Tubes supply various industrial needs in India and overseas. Aman Pipes and Tubes’ SS 439 pipes are manufactured through latest technology and strict quality checks, making them suitable for high-performance and corrosion-resistant needs. Supported by the expertise of its workforce and effective logistics, Aman Pipes and Tubes supplies products as per international standards, gaining a reputation for high quality in stainless steel piping.

Stainless Steel 439 is titanium-stabilized ferritic stainless steel with a content of around 17–19% chromium, 0.5% nickel, and minor amounts of titanium and other elements. It has superior corrosion and oxidation resistance, particularly in mildly aggressive and high-temperature conditions. The standard mechanical properties are tensile strength of approximately 415 MPa, yield strength of approximately 275 MPa, and elongation of 20%. Its microstructure provides excellent weldability and formability and is good for uses requiring strength and resistance against scaling and corrosion.

| Stainless Steel 439 Pipe Specifications | |

|---|---|

| Standard | ASTM A/ASME SA268/A731 CL |

| Dimensions | ASTM, ASME and API |

| Size | 1/8″NB TO 30″NB IN |

| Pipes & Tubes | 1/2″ NB – 16″ NB |

| ERW Pipes & Tubes | 1/2″ NB – 24″ NB |

| EFW Pipes & Tubes | 6″ NB – 100″ NB |

| Outer Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB |

| Specialized in | Large Diameter Size |

| Thickness | SCH 10, SCH20, SCH30, SCH40, STD, SCH60, XS, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated / CDW |

| Form | Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes |

| Length | Single Random, Double Random & Required Length |

| 439 | Max | Min |

| Ni | 0.20 | – |

| C | 0.01 | – |

| Mn | 0.25 | – |

| P | 0.02 | – |

| S | 0.015 | – |

| Si | 0.35 | – |

| Cr | 17.35 | – |

| Fe | 81.35 | – |

| Element | SS 439 |

| Density | – |

| Melting Point | – |

| Tensile Strength | 438 |

| Yield Strength (0.2%Offset) | 263 |

| Elongation | 22 |

| Hardness(Rockwell B (HR B) max) | 89 |

| Hardness(Brinell (HB) max) | – |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 439 Pipes from Aman Pipes and Tubes ensures quality and reliability. Our products are rigorously tested and meet stringent industry standards, guaranteeing exceptional performance. We offer customized solutions to meet the specific needs of the business. By focusing on innovation, our pipes have increased their corrosion resistance and durability. Additionally, our experienced team provides excellent customer support, ensuring a seamless experience from order to delivery. Trust Brydon for your stainless steel needs, where quality meets best.

Aman Pipes and Tubes, one of the largest suppliers of Stainless Steel 439 Pipes in Hyderabad, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 439 | 1.4510 | S43035 | SUS 439 | – | – | – | – |

| Element | SS 439 |

| Density | – |

| Melting Point | – |

| Tensile Strength | 438 |

| Yield Strength (0.2%Offset) | 263 |

| Elongation | 22 |

| Hardness(Rockwell B (HR B) max) | 89 |

| Hardness(Brinell (HB) max) | – |

Yes, we offer custom sizes for Stainless Steel 439 Pipes to meet your specific requirements. Our team at Aman Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@amanpipesandtubes.co.in.

Stainless Steel 439 Pipes find extensive application in those environments that need additional corrosion resistance and heat stability. They are widely used in automotive exhaust systems where corrosion and high temperature resistance is a must. They are also utilized in heat exchangers, power plant equipment, flue gas cleaning systems, and architectural elements. Their performance stability under oxidizing conditions, plus cost-effectiveness and long service life, qualifies them to be used in chemical processing units and other structural applications where strength as well as aesthetics matter.

©2024 Aman Pipes and Tubes . All Rights Reserved.